Hemp

HEMP

Crop Profile

Get Involved!

What is hemp?

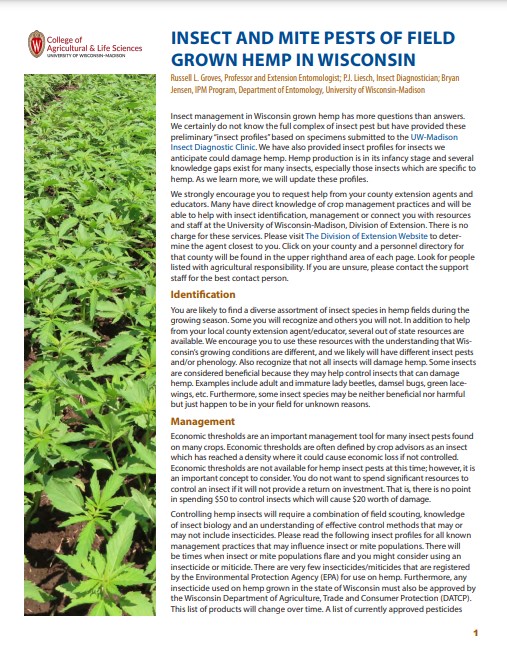

Hemp (Cannabis sativa L.) is a versatile crop that can be used for its stalk (bast fiber and/or hurd), seed (grain or oil), or flower (bud or oil); it is commonly said that there are over 25,000 products that hemp is used in today. Considered one of the oldest crops in cultivation, hemp was once widely grown as a commodity fiber crop in the United States from the mid-18th century until its decline in the 20th century, brought upon by shrinking demand and government regulations aimed at marijuana (drug-type cannabis). Restrictions led to its eventual ban in 1970 with the passage of the Controlled Substances Act. Shifts in public opinion regarding cannabis and grassroots lobbying led to the legalization of permitted research beginning with the 2014 Farm Bill. Passage of the 2018 Farm Bill subsequently removed hemp from the list of controlled substances and legalized commercial production of hemp in the US, opening the door for re-development of a domestic hemp industry. Wisconsin responded swiftly by launching a pilot hemp program in 2018 until January 2022, when it relinquished authority over to the USDA.

What is the difference between hemp and drug-type cannabis?

Hemp and drug-type cannabis (commonly called “marijuana”) are different types of plants within C. sativa that are distinguished by their chemical composition. Hemp is legally defined as cannabis containing not more than 0.3% THC, the psychoactive compound found in C. sativa. Conversely, if the THC level is greater than 0.3%, the plant is classified as drug-type cannabis. Drug-type cannabis plants have been bred to produce a high amount of THC in the range of 10 to 30 percent.

What is hemp grown for?

Hemp is grown as a food and fiber crop and harvested for its seeds (grain), stalk (bast fiber and hurd) and flower.

- Hemp seeds (grain) can be processed into hemp hearts and used in a variety of food products such as granola and hemp milk. Hempseed oil extracted from the seeds are used in cooking oil, dietary supplements, personal hygiene products, paints, solvents, lubricants, and medicinal and pharmaceutical products.

- Hemp stalks are harvested for their fibers, which are used to manufacture hundreds of products, including rope, paper, construction materials, carpeting, textiles, insulation, animal bedding and bioplastics. There are two main types of fibers within the plant, the bast and the hurd, and each has different qualities and uses.

- Hemp flower is harvested for smoking and the extraction of cannabinoids, especially CBD. Cannabinoids are naturally occurring compounds found in the resins of C. sativa flowers. Over one hundred cannabinoids have been identified to date and they have shown some promise in helping treat certain health conditions such as epilepsy and anxiety.

How is hemp grown?

Production practices for hemp differ based on intended use. Hemp for grain and fiber production is typically grown on a large scale using conventional farm equipment such as a grain drill, mower, combine, and baler. Seed is harvested using a grain combine while stalks for fiber are cut and baled using haying equipment. Stalks must go through a process called retting between cutting and baling to help separate the bast from the hurd fibers. Hemp may be grown as a dual-purpose crop for grain and fiber.

Hemp grown for cannabinoid production is much more labor intensive and akin to specialty/vegetable crop production. Plants are usually started from feminized seed and transplanted into rows of black plastic lined with drip irrigation. Plants are spaced much further apart, with recommendations ranging from 1 foot on-center up to 6 feet on-centers. At harvest time, plants are cut by hand at the base (a machete is usually the tool of choice) and hung up to dry in a barn until further processing/extraction may take place.

For more detailed information on hemp production, see the Resources and Information section below.

Research Status and Priorities

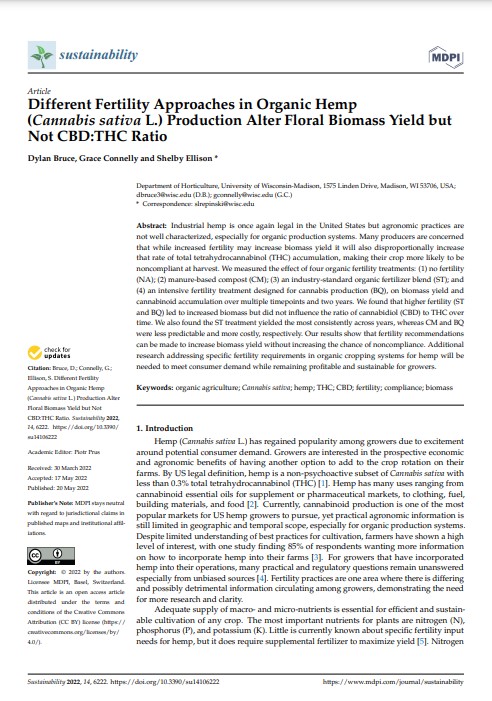

As an emerging and highly regulated industry, the U.S. hemp sector faces unique challenges to sustainable growth. Despite the overwhelming interest in hemp, there is a significant knowledge gap regarding best practices for sustainable hemp production.

The Ellison Lab at UW-Madison is working to address current high priority research areas determined by a hemp needs assessment conducted in the winter of 2019-2020. Regulatory compliance, flower quality, seed characteristics, insect management, weed management, and disease management are among the top priorities.

The Wisconsin Crop Innovation Center (WCIC) is also conducting important, novel hemp related research. Recently, the WCIC successfully developed the first transgenic hemp variety.

The Midwestern Hemp Research Collaborative (MHRC) is a research group consisting of representatives from Michigan State University, Purdue University, University of Illinois at Urbana-Champaign, University of Wisconsin-Madison and Michael Fields Agricultural Institute. All data generated by the MHRC and associated trials are integrated into the Midwestern Hemp Database (MHD), a public online repository consisting of the High Cannabinoid Database and Hemp Grain and Fiber Database for hemp variety performance data used to support stakeholder decision-making and risk mitigation. Since its creation in 2020, the MHD is the largest public hemp performance dataset we are aware of.

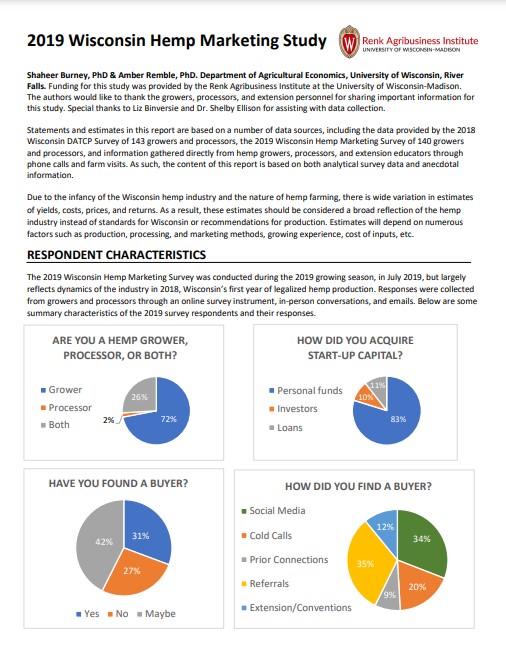

Markets

With the passage of the 2018 Farm Bill, the legalization of hemp in the United States has provided a unique opportunity to build an entirely new agricultural sector and industry with opportunities along the whole supply chain. Unfortunately, current regulatory and market risks associated with hemp production have made establishment of this industry challenging. UW-Madison Extension aims to help support this emerging industry and those looking to enter it.

Interested/new growers may want to look at the following hemp budget enterprise models to help guide their decision making process.

Plant Material

With limited seed certification standards in place, substantial variation across plant uniformity and performance metrics has been observed in hemp throughout the Midwest. This can make selecting reliable cultivars (and seed providers) a challenge.

Fortunately, there are some resources available that can help you make the most informed decision possible.

For High-Cannabinoid Hemp (CBD or CBG)

- The High Cannabinoid Database can be used to evaluate cultivars for cannabinoid production and may be a good place to start.

- The Cultivar Check Program utilizes a network of grower-cooperators to conduct participatory on-farm trials to evaluate harvest schedules for select “good potential” cultivars.

- Replicated university station trials evaluating regional variety performance.

For Industrial Hemp (Grain/Fiber)

- The Hemp Grain and Fiber Database can be used to evaluate cultivars for cannabinoid production and may be a good place to start.

- Replicated university station trials evaluating regional variety performance.

- Association of Official Seed Certifying Agencies (AOSCA) Hemp Varieties Eligible for Certification

Yield and other agronomic performance metrics often vary across (and within) varieties. Grower experience/skill, geographic location, and weather also play a tremendous role in production. For this reason, growers may utilize the MHD for cannabinoid development but should prioritize university station trials as more useful/accurate sources of information for regional agronomic performance.

- Example: A Wisconsin grower could search the Midwestern Hemp Database to determine a list of compliant hemp cultivars. From there, the cultivars could be cross-referenced with their agronomic performance in the University of Wisconsin-Madison hemp variety trials or the Cultivar Check Program prior to making their final selections.

Rules and Regulations

Hemp producers and processors are required to follow their respective state and federal regulations regarding hemp production and registration. Prospective growers must register within their state and adhere to the most current rules and regulations. Regulations are subject to change from year to year with the development and approval of proposed program rules. It is important to note that these regulations may vary across state lines.

Wisconsin relinquished authority over their state hemp program to the USDA beginning in January 2022. Please see the links below for more information on the USDA Hemp Program, including how apply to become a hemp grower or processor.

Interested in getting a hemp production or processing license? Before you apply, take some time to review the USDA Hemp Final Rule to familiarize yourself with the rules and regulations you must abide by.

A little overwhelmed by the rules and regulations? Take a look at this USDA Hemp Final Rule Guide to walk you through it!

Have questions? Take a look at the USDA Hemp FAQ page or contact the USDA at farmbill.hemp@usda.gov.

Decided you want to apply for a hemp grower/processor license? Apply at the USDA Industrial Hemp Website.

Looking to get your hemp tested for compliance? Review the USDA Sampling Guidelines for Hemp as well as the Guidelines for Hemp and contact one of the USDA Approved Analytical Laboratories.

Interested in learning more about industrial hemp production in the U.S.? Take some time to review the 2022 USDA National Hemp Report.

Grant Opportunities for Producers

Opportunities for Engagement

Do you grow, process, or sell hemp or hemp products? If so, we need your help! UW-Madison offers many opportunities to get involved in the research and development of a hemp industry in the Upper Midwest. We are looking for collaborators on the following initiatives.

Aware of any feral/wild hemp locations and interested in being compensated for your knowledge? Interested in contributing to a larger hemp genetics and breeding research effort? Contact Dr. Ademola Aina for more information.

Experienced row crop producer interested in being compensated for your skills/knowledge? Looking to work on the cutting edge and conduct participatory on-farm trials of grain/fiber hemp with costs of seed and cannabinoid testing covered? Contact Phillip Alberti for more information or apply here.

Interested in receiving significantly discounted cannabinoid testing costs in exchange for data sharing? Interested in contributing to the largest public hemp database in the Midwest which has been utilized to inform positive policy change at the federal level? Visit the Midwestern Hemp Database (Grain and Fiber, High CBD) or contact Phillip Alberti for more information.

Are you a hemp grower with experience managing pest and disease issues? The Ellison lab invites you to take a survey to share information on the pest populations you manipulate, management strategies you use, and how these strategies may affect those populations. The first 50 respondents will be entered in a drawing to win a $10 Kwik Trip gift card. Take the survey here. For questions, contact Cheyanne Mattie.

Having hemp disease issues in your field? In the Ellison group, we aim to survey hemp fields and diagnose crop diseases to determine which plant pathogens are currently in hemp fields across Wisconsin. Interested in learning more about plant disease diagnostic services? Contact Dr. Derrick Grunwald for more information.

Experienced hemp grower? Looking to conduct participatory on-farm trials of high cannabinoid hemp with costs of seed and cannabinoid testing covered? Interested in networking with other growers while helping to develop compliant harvest schedules for high cannabinoid hemp cultivars? Consider getting involved in the Cultivar Check Program! Contact Phillip Alberti for more information or apply here.

Resources and information

Read

Watch

These videos cover a range of topics including hemp for fiber, grain, and CBD production. More videos can be found on the the Wisconsin Hemp YouTube Channel. Also check out the Wisconsin Hemp by Hand Webinar Series for interviews with hemp industry leaders and real world applications of hemp.

UW-Madison Hemp Research Updates

Bryan Parr (Legacy Hemp)

Dr. Shelby Ellison (University of Wisconsin-Madison) and Leah Sandler (Michael Fields Agricultural Institute)

Leah Sandler (Michael Fields Agricultural Institute)

Dr. Shelby Ellison and Dr. Rodrigo Werle (University of Wisconsin-Madison)

University of Wisconsin-Madison Extension and Sunny Skies CBD

Listen

Resources for Tribal Communities

Canndigenous

Hempstead Project Heart

Indigenous Cannabis Coalition

Indigenous Hemp Conference

Marijuana Legalization in Indian Country: Selected Resources (Centers for Disease Control and Prevention)

More Resources

Colorado State University

Cornell Hemp

Kentucky State University

Michael Fields Agricultural Institute

Oregon State University

Purdue University

University of Illinois at Urbana-Champagne

University of Kentucky

University of Vermont

University of Wisconsin-Madison Hemp Compass (financial planning tool)