Equipment to Rake and Merge Hay and Forage

K.J. Shinners and R.T. Schuler

Today, hay and forage producers have a wide variety of equipment options for raking and merging swaths or windrows. Selecting the proper equipment and operating it correctly will help to ensure high quality forage and a cost effective harvesting system. Several studies have been conducted evaluating the equipment performance and provide useful information in selecting the equipment that best fits a specific forage harvesting system.

Market Segmentation of Rakes and Related Equipment

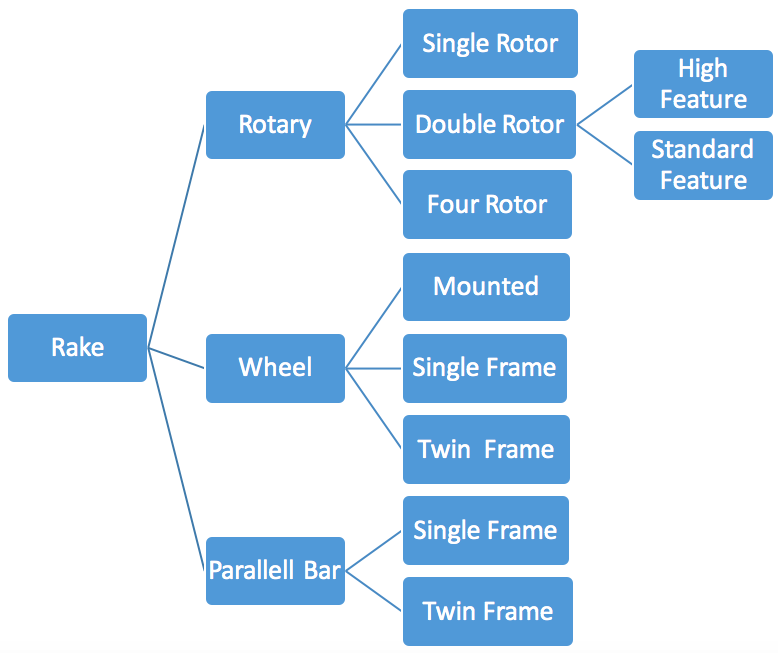

Rakes are often used for four purposes: to invert the crop to allow wet hay on the bottom of the swath to be exposed to sun and wind, to displace the swath from wet to dry ground, to merge swaths together to match the windrow density with harvester or baler capacity, and to narrow the swath into a windrow narrow enough to meet the width of the harvester or baler pick-up. The North American market for equipment that is used to rake forage crops after cutting can be illustrated as follows:

The tractor’s PTO or hydraulics are generally used to power rotary and parallel-bar rakes. This gives them sufficient power to manipulate wet, heavy swaths or windrows that will be harvested as silage. Wheel rakes are not powered directly by the tractor. Rather, forward motion of the tractor and the engaging of the wheels in the crop or soil drive the wheels and because of this they often have difficulty moving wet, heavy swaths or windrows. Therefore, wheel rakes are often limited to raking drier crop that will be harvested as dry hay.

Wheel rakes are available in a wide variety of designs that can be generally grouped into the three categories above. Because they do not require a powertrain, wheel rakes are the lowest cost segment and are designed to rake widths up to 36 ft. This width allows two swaths from a 18 ft. cut mower-conditioner to be merged in a single pass. No other rake type offers such size at such low cost. The mounted and single frame wheel rakes are dominated by imports from Italy and are low feature and low cost units. These units are not common in the Upper Midwest because they lack the needed width or capacity to manipulate swaths from the typical mower-conditioner or windrower. The most common type of wheel rakes is the twin frame design. The twin frame rake can be further divided into low, high and premium feature rakes. Low feature rakes typically have the wheels mounted on the rear of the frame, must be folded manually and also have manual width adjustment. Hay will be rolled in front of the wheels, so locating wheels on the rear of the frame limits capacity because of potential for crop interference under the frame. High feature rakes typically have wheels mounted in front of the frame to handle larger crop volumes and have hydraulic controls for folding and width adjustment. These rakes will also feature articulated frames that allow wide rakes to follow ground contours with less crop loss. Premium wheel rakes feature larger diameter wheels with stiffer teeth and larger overhead frames to accommodate these larger wheels. These rakes are more typically seen in the arid western US and are popular with commercial hay producers. No matter the design, the wheel rakes will have springs whose tension can be adjusted to change the weight carried on the wheel. If wheel float is set too light, the wheels will float over the crop and leave some crop behind. If wheel float is set too heavy, tooth wear will be accelerated and the wheels will dig into the ground, creating greater soil and rock contamination. Most designs require that spring tension be adjusted manually on each wheel, so this adjustment is often neglected in the heat of the hay making battle. A concern often expressed with wheel rakes is the tendency for the hay to be “roped” after the raking operation, which can reduce air movement through the windrow and slow the drying rate. Data on drying rate and leaf loss of various rake types will be covered later.

Parallel-bar rakes were the dominant machines used to manipulate forage crops in the Upper Midwest for many years, but sales of these machines are declining annually. Although parallel-bar rakes are considered less aggressive than wheel rakes, parallel-bar rakes are more expensive and are not available in wider widths. The parallel-bar rake also has a powertrain and many moving parts to maintain. Twin frame parallel-bar rakes are more expensive than single frame rakes because they typically have larger baskets and also have added frame, controls and hydraulics. Although parallel-bar rakes will continue to have a place in the rake market in the future, the share of these rakes will continue to erode toward rotary rakes.

Rotary rakes originated in Europe to handle the heavy, wet grasses that are harvested there. Other rake types could not handle the tough conditions experienced in Northern Europe. Rotary rakes were introduced to the North American market in the 1980’s and they have slowly but surely gained market share since that time. Single rotor rakes are the most popular. Although mounted or pull-type rotary rakes are available, the pull-type type is dominant in the Upper Midwest. The two primary features that differentiate single rotor rakes are the rotor diameter and the number of arms. Larger diameter rotors will improve the swath width handled and more arms will increase the capacity. Standard feature twin rotor rakes are typically designed to sweep two swaths toward the center, forming a single merged windrow; the distance between the rotors is not adjustable. The distance between the two rotors, and hence the coverage width, is adjustable on the high feature twin rotor rake. Some twin rotor rakes have identical rotors on both sides so that all hay is moved in the same direction. This allows merging to the side of the machine, rather than the center, so that when the next pass is made, another merged windrow is laid beside the first. This may be done to meet the capacity of a self-propelled forage harvester. Four rotor rakes have a retail price of over $40k, so they have a limited market in the Upper Midwest. These machines would typically be used to merge crop for large self-propelled forage harvesters. Rotary rakes have a deserved reputation for creating a well-formed, less roped windrow that allows good air circulation and good crop drying. For this reason, these rakes are becoming increasingly popular to merge the crop for large square balers because of the need to get hay very dry in these large bales. Care must be taken with this rake type not to sweep the ground too aggressively to avoid soil and rock contamination of the windrow. Another important adjustment is the rotor to ground speed ratio. The correct combination of tractor gear and engine speed must be found so that all the crop is swept into the windrow, but the rotor is not turning so fast that leaves are battered from the stem. Rotary rakes are the most expensive rake type discussed because they are the heaviest and require the heaviest frame, and the cam-actuated gearbox that drives the rotor is more complicated and expensive. The cam/gearbox can be quite expensive to repair if failure occurs.

Many forage producers in the Upper Midwest who chop silage know the expense and frustration of running a rock into the forage harvester cutterhead. Merging multiple swaths into a single windrow with a rake can add to this risk because the crop is dragged along the ground as it is merged. Also, soil contamination into the windrow can lead to problems with clostridia fermentation and high ash content in the dairy ration. As forage harvesters have grown in capacity, there has been a need for merging more swaths into a single windrow. This has led to the development of a machine referred to as a windrow merger. The major difference between this machine and a rake is that the merger lifts the crop onto a belt conveyor that is used to move and deposit the swath into the desired position so that the crop is never dragged along the ground. The windrow merger can be used for either silage or dry hay although its primary use is silage crops. Most machines can deposit crop to the left or right simply by changing the direction of the hydraulically driven belt conveyor. Before purchasing a windrow merger, it is important to consider the compatibility of the mower-conditioner width, merger pick-up width and the forage harvester or baler pick-up width. Some mergers can be configured with a belt extension to help width compatibility. Windrow mergers are configured as either single or double windrow machines. Single windrow machines can merge either two swaths into one with one pass or three swaths into one by making a return pass on the other side of the new doubled windrow. Double windrow mergers are more expensive at retail list price than single mergers because they have much heavier frames and complicated folding or swiveling features for transport. Most double windrow mergers can be configured to deposit crop to the left, right or to the left and right simultaneously. Operating by depositing to the left or right exclusively provides the option of merging either three or five windrows into a single windrow. Lifting two and depositing onto a third merges three windrows. Lifting another two on the return pass on the other side and depositing on the newly tripled windrow merges five windrows. Windrow mergers are configured with either conventional tine-type pick-up or tine-belt pick-up similar to a windrow pick-up for a grain combine. Some mergers also have optional inverter shield that can be mounted on the output of the cross-conveyor to help invert crop for better drying.

Windrow inverters pickup one windrow and lay it on the ground up side down. They are configured quite similar to windrow mergers with a conventional or belt-type pick-up, cross-conveyor belt and inverter shield at the conveyor output. The primary differences between a merger and inverter is that the inverters have a narrow pick-up width that can only accommodate a narrow windrow and the inverter is quite a bit lighter-duty than a merger. The inverter is not intended as a merging device. Rather, the inverter is intended to move an already formed windrow off of wet ground and invert it for faster drying to dry hay moisture.

The final type of hay manipulation tool that should be mentioned is the tedder. The modern tedder was developed in Europe and most tedders that are sold in the Upper Midwest are imported from Europe. Tedders are used to spread crop into a swath as wide as the cut width of the mower-conditioner. This not only aerates the swath, but more importantly it allows all the sunlight that is striking the field to be used to dry the crop. When crop is placed in a narrow windrow, much of the sunlight strikes bare ground and does not aid in the crop drying. Besides good crop conditioning, the most important factor in achieving fast forage drying is the width of the formed swath. If tedding offers so many benefits, why isn’t it a common practice in the Upper Midwest? There are several reasons for this. First, tedding is an aggressive action and is acceptable for grasses where leaf loss is less of a concern. But for alfalfa there is concern that tedders will cause unacceptable leaf loss, especially if the tedding is done when the crop is partially dry and the leaves are brittle. Second, tedding adds an additional step in the hay making process: cutting, tedding, raking and baling. Third, a tedder adds an additional machine expense to the already substantial line-up of hay making equipment. Lastly, sometimes it is beneficial to lay the crop in a narrow swath so that damp ground can be dried out. This will allow a dry location for a raked windrow to be placed. There are so many different designs and configurations of tedders available that it is not possible to cover all of them here. The most common types in the Upper Midwest are pull-types with two or four rotors. These are relatively simple machines with relatively low retail list prices. The larger six rotor machines are more complicated and much more expensive because of the folding requirements for transport. Six rotor machines are often fully mounted, so they require a fairly large tractor to operate. Although there are some downsides to using a tedder, forage producers in the Upper Midwest, especially those with alfalfa-grass mixtures, who are looking for fast drying to dry hay moisture, may find the tedder quite beneficial.

Another tedder design, sometimes referred to as a fluffer, does not move the windrow nor change its width. The machine has parallel rake bars that engage the windrow at a faster rearward speed than the forward travel speed. This action causes the forage in the windrow to be moved rearward and slightly upward resulting in an aerated windrow that allows air to move through it for improved drying. This machine can be helpful in increasing the drying rate after a heavy rainfall.

Machine Performance Studies

Rakes and related equipment can be evaluated based on field losses, drying rates, windrow shape and condition, ability to move heavy swaths and ability to create windrow free of rocks and other debris typically found in the field. When evaluating this equipment, the forage producer must evaluate their situation to ensure high quality forage and to meet their needs with respect to their yields and cutting and harvesting equipment size.

Losses and Drying Rates

This equipment should be selected and operated based on the criteria to create minimal losses and maintain rapid field drying which will ensure high quality forage. The manner in which the equipment handles the swath impacts the level of loss and the resultant windrow. Handling methods range from picking up the swath and laying it down to rolling the swath across the ground surface.

Most of the research has involved the losses and drying rates associated with these machines. In numerous cases the forage quality was evaluated, which may be related to the losses; usually high quality leaves, and drying rate.

In a study by Savoie et al. (1982), a parallel-bar rake was compared to a rotary rake in conditioned and non-conditioned alfalfa. They found no difference in the drying rate but the rotary rake had slightly higher losses. Raking was done near 40 percent moisture, wet basis. They found tedding increased the drying rate slightly but the results were not very consistent. During good drying conditions, tedding did not appear to be beneficial but may be beneficial after a heavy rain, which creates a windrow that was dense and matted.

Using artificial stubble, Buckmaster (1993) evaluated a parallel-bar and a wheel rake. The parallel bar rake had about two percentage units less loss throughout a forage moisture range of five to fifty-five percent, wet basis. In an Ohio study reported by Claas, three rakes (wheel, rotary and parallel-bar) were compared with respect to drying rate based on moisture content as forage dry down approached baling moisture. In the first cutting for an orchard grass-alfalfa mix, the rotary rake had the lowest moisture (20.9 percent) while the wheel rake had the highest moisture (25.0 percent). The parallel-bar rake was intermediate. For the second cutting alfalfa, the rotary rake had lower moisture (20.4 percent) than the other two rakes (22.5 percent for the parallel-bar and 23.0 percent for the wheel rake). In a third cutting of alfalfa of an orchard grass mixture, the differences in moisture between rake types were not significant.

Garthe et al. (1988) compared a parallel-bar rake with a windrow inverter and found no difference between the two devices in terms of drying rate or crop quality (based on crude protein content). Shearer et al. (1992) compared a parallel-bar rake with two different windrow inverters. They found no difference between the three machines with respect to the drying rates or losses. In a study of several rakes and a windrow inverter, Hoover (1996) found that the inverter and the parallel-bar rake had significantly less loss than the other rake types which included a wheel rake and several rotary rakes. In this study, the drying rate among the different rakes was very similar.

Savoie and Beauregard (1988) studied four windrow inverters that significantly increased the drying rate compared to a control with no manipulation of the forage in a windrow. In addition, they indicated that an inverter could advantageously replace a hay tedder.

Although no research has been reported on windrow mergers, their losses would be expected to be similar to the windrow inverters because they both pickup the windrow and do not move it across the ground. The drying rate of forage gathered with a windrow merger is generally not an issue because merging usually takes place right before the forage harvester.

Windrow Shape and Condition

To produce a consistent, high quality forage the raked or merged windrow must be uniform to ensure the moisture is the same throughout the windrow. Based on field experience and observations, the rotary rakes produce a more uniform and less roped windrow than wheel or parallel-bar rakes. Windrow inverters and mergers will not produce a roped windrow, but can often produce a non-uniform windrow if the belt does not properly take the crop off the pick-up. In all cases the equipment must be properly adjusted and operated to obtain the most uniform windrows.

It is important to produce windrows free of rocks, soil and other debris to avoid problems with forage harvester knife wear, knife damage, clostridia fermentation (especially in high moisture silages) and excess ash content in the feed. Equipment that rolls or slides the windrow across the ground will have a greater risk of having rocks and soil contaminate the windrow. This becomes more important with high capacity forage harvesters requiring a greater distance for swaths to be moved. Machines that pickup the swath, displace it with a cross-conveyor and then lay it down on the ground at another location will have less risk of contaminating the windrow. In a study of rock movement caused by rakes and a windrow inverter, Hoover (1996) found that the inverter and wheel rake moved significantly fewer rocks than the other rake equipment. The rotary rake moved significantly more rocks than the other rakes. Although no studies have been done with windrow mergers, because they handle the windrow similar to an inverter, it is safe to imply that the merger would move fewer rocks.

With increased forage yields, raking and merging equipment must be sufficiently aggressive to move the large quantity of forage. Equipment that is ground driven will have greater difficulty picking these swaths. These would include the wheel rakes and ground driven parallel-bar rakes. PTO and hydraulic driven rakes and mergers can become more aggressive by maintaining a higher operating speed relative to the forward travel speed.

Today, forage producers have many options in equipment for moving swaths and creating windrows. Careful selection of this equipment should be made to choose a system the machine that best meets the needs with respect to crop yield and cutting and harvesting machine size. Also it is extremely important to properly adjust and operate these machines to ensure minimum losses and rapid drying.

References

Buckmaster, D. R. 1993. Alfalfa raking losses as measured on artificial stubble. Transactions of the ASAE. 36(3):645-651.

Garthe, J. W., P. M. Anderson, R. J. Hoover and S. L. Fales. 1988. Field test of a swath/windrow hay inverter. ASAE Paper 88-1549. ASAE, St. Joseph, MI. 15 pp.

Hoover, L.L. 1996. A comparative rake study of dry matter loss, drying rate, and rock movement in alfalfa fields. B.S. Honors Thesis. The Pennsylvania State University. 33 pp.

Rotz, C. A. and P. Savoie. 1991. Economics of swath manipulation during field curing of alfalfa. Applied Engineering in Agriculture. 7(3)316-323

Savoie, P. C. and S. Beauregard. 1988. Hay windrow inversion. ASAE Paper 88-1548. ASAE, St. Joseph, MI. 13 pp.

Savoie, P., C. A. Rotz, H. F. Bucholtz and R. C. Brook. 1982. Hay harvesting system losses and drying rates. Transaction of the ASAE. 25(3) 581-585, 589.

Shearer, S. A., G. M. Turner, M. Collins and W. O. Peterson. 1992. Effect of swath and windrow manipulation on alfalfa drying and quality. Applied Engineering in Agriculture. 8(30) 303-307.