Identifying and Managing Soil Compaction

in Field Crop Production

by Richard Wolkowski

Division of Cooperative Extension of the University of Wisconsin

Causes of Soil Compaction

The need to conduct field operations in a timely and efficient manner has renewed concerns regarding the “productivity robbing” effects of soil compaction. Today’s farmer is managing greater numbers acres with the pressure to complete operations in a timely manner. Manure management and harvesting equipment, and even tractors are much larger than they were just a few years ago. Operations must often be conducted when soils are wet. These factors have become problematic on large dairy farms and other livestock operations where frequent and extensive manure application is necessary.

Typically, soils are 50% solid and 50% pore space, with about half of the pore space filled with water. Soils are most easily compacted when the water content soil is at, or just above, its field capacity. Pressure from wheel traffic and tillage consolidate the soil, first reducing the number and size of larger pores by re-arranging soil aggregates. Heavy loads can destroy the soil structure itself. The resulting soil has a greater density and lower porosity. Pores, especially the larger ones, are important for water and air movement. The potential for compaction increases as the soil clay content increases, however sandy soils can become compacted, especially if sand particles are of different sizes.

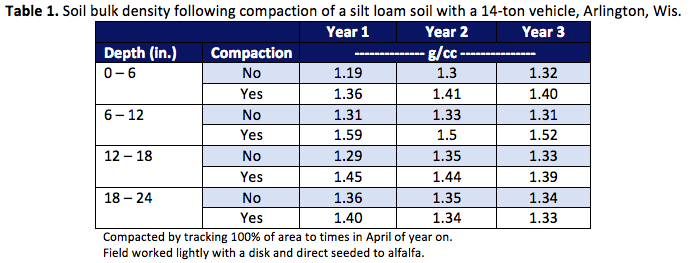

Bulk density, defined as the mass of soil per unit volume, is one measure of soil compaction. Table 1 shows the soil bulk density over three years following wheel-traffic compaction from a 14-ton vehicle. This field was compacted over its entire area in the spring and worked lightly prior to seeding alfalfa. The change in bulk density is visible well below the plow layer and is relatively unaffected over the three years. This suggests that compaction can occur in the subsoil and that its effects are long-term and are not quickly ameliorated by natural factors such as freezing and thawing or wetting and drying.

Diagnosing Compaction

The signs and symptoms of compaction can be found by examining the response of the soil and crops to wheel traffic. Compacted soils have imperfect drainage, resulting in ponding and increased runoff. Where the structure is destroyed, the soil will be massive and cloddy. A horizontal or platy type of structure can also develop in the upper soil layer. The loss of structure disrupts natural pores and channels important for water and air movement, and the resulting increase in soil strength impedes root proliferation.

Compaction effects are also exhibited in the growth of the plant. Uneven height growth is common where one appears normal and the adjacent plant is stunted. The root system will be malformed such that horizontal development occurs at the restrictive layer. Nutrient deficiencies, especially K, can develop in response to poorer aeration in the soil. Compaction almost always causes a loss in yield. The magnitude of the yield loss is often related to the incidence of water stress conditions during the growing season.

A common assessment device is the penetrometer, a cone tipped rod attached to a gauge that is pushed into the soil at a constant rate. It measures the resistance to penetration and somewhat simulates the environment that a growing root would experience. Simple penetrometers are pushed by hand and have a dial that translates the force into green, yellow, and red zones. Advanced units are mechanically driven and have sensors that can be calibrated to measure and record the resistance in units of pressure. The soil water content will have a significant impact on the penetration resistance. It is recommended that measurements be taken when the soil is at its field moisture water content. Soil bulk density is a useful measurement of compaction and its measurement provides for the calculation of porosity. Most farmers or crop advisors do not have the appropriate tools to make this measurement.

There is no critical level of any soil measurement that universally identifies the degree of soil compaction that will result in a crop yield reduction. Penetration resistance, as previously indicated, is greatly affected by the soil water content and will obviously be very high if readings are taken in dry conditions. Bulk density is not affected by moisture, but is a function of soil texture. It is recommended that any measurement should be made to develop a relative comparison between areas where compaction is suspected and where it is unlikely. For example, compare a headland with an area in the main part of the field or a wheel-tracked area with a non-tracked area. It is often useful to excavate the soil to examine the soil structure and evaluate plant root distribution. Be sure to note the depth at which compaction occurs to determine the depth of the restrictive layer. Knowledge of the location and size of this layer will determine if deep tillage can remove the compaction.

Soil Compaction Research

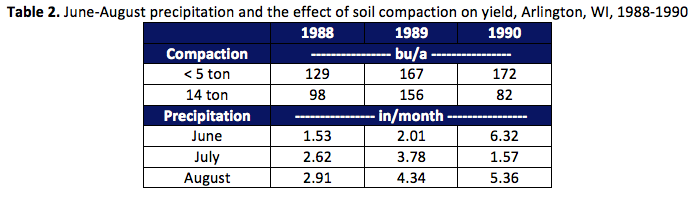

The effect of compaction has been studied by this author at several locations in Wisconsin. Because compaction has such a profound effect on the soil tilth its effects are variable from year-to-year depending on weather conditions. A study was conducted on corn at Arlington from 1988 – 1990. This period included a drought year and two years that might be considered normal. Table 2 shows the corn yield for those years and monthly total precipitation for June – August. Clearly, yield was reduced in the dry year. Yields were similar in the normal years if the soil wasn’t compacted, but were drastically reduce in 1990 in the compacted plots. This reduction is likely the result of moisture stress caused by a reduced root system and the relatively low precipitation received in July when the corn was pollinating.

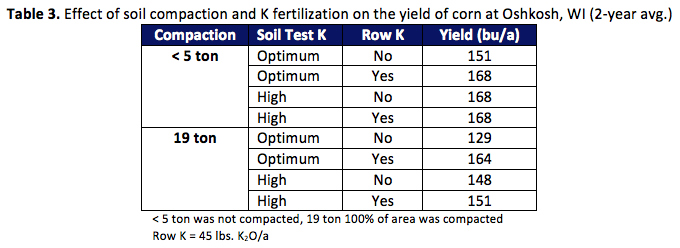

Another study examined the interaction of K fertility and corn yield on a Kewaunee silty clay loam soil near Oshkosh. The results of this study are shown in Table 3. The two compaction treatments included one where traffic was confined to inter-row areas with small equipment and another where the entire plot area was compacted with a 19 ton combine. Soil test K had been adjusted to either the optimum or high category and row K fertilizer was applied to half of the plots. Compaction significantly reduced yield. Some of the yield loss was recovered by K fertilization, but the best yields were found when the soil was not compacted and the crop was fertilized adequately.

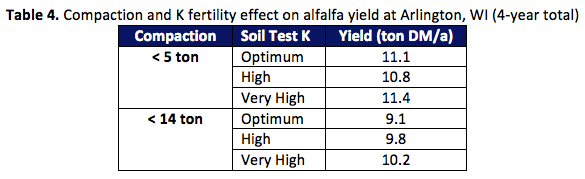

A similar study was conducted at the Arlington Agricultural Research Station on a Plano silt loam soil that examined the effect of compaction prior to the direct seeding of alfalfa and K fertilization. Compaction in forage production can be significant, especially where manure is applied prior to direct seeding. Table 4 shows the yield reduction associated with compaction over the life of the alfalfa stand (seeding year plus three hay years). Most of the yield loss occurred in the seeding and first hay year. As with corn, a response to K fertility was found. It is believed that the reduction in porosity caused by compaction reduces oxygen availability to roots, limiting root respiration, and thereby limiting K uptake. Potassium fertilization maintains a higher level of K at the root/soil interface and apparently promotes K uptake under restricted conditions.

Alleviating Compaction

Whenever possible soil compaction should be avoided. Practices such as limiting operations on wet soils, reducing load weight when possible, and controlling traffic will go a long way toward limiting compaction and maintaining soil productivity. Adding extra tires (duals) will spread the vehicle weight over a greater area, but will likely not reduce compaction. In fact, duals may encourage operations on wetter soils and compact a greater soil volume. Control traffic by limiting practices, such as “chasing the combine” with grain carts or driving grain trucks or nurse trucks for manure or fertilizer applications in fields.

Often deep tillage or subsoiling is considered when compaction problems are severe. Some farmers routinely subsoil as a form of primary tillage. Subsoiling can be conducted with a variety of tillage tools that will have a variable effect depending on soil conditions, the depth of tillage, and the tool used. A four year on-farm research study conducted recently in Manitowoc County showed that subsoiling with a relatively narrow straight shank produced higher yields than an aggressive parabolic tool that shattered the entire soil volume. It is possible that the soil strength was minimized with the more aggressive tool and soil conditions were less favorable following tillage. Yield differences were significant in three of four years. This response was site-specific as similar studies conducted at other locations did not show a response to subsoiling.

Before deciding to subsoil it is important to diagnose the existence of compaction and to record the depth of the restrictive layer. If subsoiling is done it should be conducted 1-2 in. below the layer. Other subsoiling considerations include:

- Some subsoiling operations will bury too much crop residue and may affect conservation planning

- Subsoiling that inverts the soil may bring clay and less fertile soil to the surface

- More stones may have to be picked

- 40-50 hp per shank is needed to pull most subsoilers

- Always include untreated check strips to determine if subsoiling is beneficial

Summary

Soil compaction problems will continue to be an issue in modern agriculture. Use common sense to avoid the occurrence of compaction. Reduce loads, stay off wet soils, and control traffic. Maintain soil fertility, especially with respect to K. Use a complete starter fertilizer for corn and be sure to re-supply crop K removal for alfalfa. Look for compaction symptoms and physically identify the existences of a restrictive layer before conducting subsoiling operations. Do not abuse the soil in the fall, expecting that over-winter condition will correct compaction.

![]()