Large Baler Research and Storage Ideas

by Ronald T. Schuler, Extension Agricultural Engineer

Many alfalfa producers look to harvest their alfalfa as intermediate (about 30 inches × 30 inches × 5 feet) square bales. This is an excellent method for handling dry alfalfa hay especially if it is going to be marketed.

Because the intermediate square bales are denser than small square and large round bales, the recommended storage moisture is two to three percent less than small rectangular bales. Recommended bale moisture levels for storage with minimal losses may be difficult to attain in humid Wisconsin weather conditions. Harvesting large square bales above 17 percent moisture will require a preservative for good bale storage or plastic wrap may be used to maintain forage quality.

Preservative Research Results (Wisconsin)

In 1997 and 1998, Shinners studied preservatives and ventilation holes for intermediate square bales at moistures from 14 to 28 percent. The preservatives were propionic acid and a bacterial inoculent. Ventilation holes of three and five inches in diameter were two treatments evaluated for reducing dry matter loss and maintaining forage quality. Four different trials or cuttings were evaluated. Following are his findings:

- Bales treated with propionic acid remain higher moisture during storage,

- Propionic acid produced less heating at the higher moisture content,

- Ventilation holes in the bales did not produce less heating.

- None of the methods reduced dry matter loss, and

- Dry matter loss was less than 4% when baling at moistures below 16%.

Bale Wrapping Research Results (Wisconsin)

At the Lancaster Agricultural Research Station, plastic wrapping of intermediate bales was evaluated for bales at 21 to 40% moisture during 1997. Undersander and others studied the effect of time between baling and wrapping and the number of plastic layers. Following are their results:

- Bales (800-1200 lbs) need to have 2 to 3% less moisture at baling than small squares,

- Bales should be wrapped within 24 hours after baling,

- Plastic wrapping bales at 21 to 38% moisture adequately preserved them, and

- Four layers of 1.5 mil plastic (50% overlap, twice over) was adequate.

Bale Silage Storage Using Plastic (Wisconsin)

In a study conducted in the late 1980’s, Straub and others evaluated plastic covers, bags and wrap with round bale silage. The plastic covers were used to protect the bales stacked three high in a triangular formation. Bale bags were designed to enclose one bale each. Also the use of propionic acid was evaluated. They found:

- Bale wrapping produced the most reliable results, and

- A preservative is needed with bale bags and covers.

Limited research results are available on bale tubes and line wrapping. The key to their success will be their ability to seal the bales and prevent any air from getting inside the plastic.

Preservative Recommendations

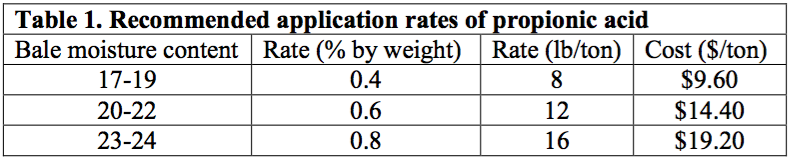

Some preservatives that have been used are anhydrous ammonia, inoculants and buffered propionic acid. Although anhydrous ammonia costs less, handling and safety problems make propionic acid a better preservative. The recommended application rates for large square bales are listed in Table 1, where the propionic acid concentration is 75 to 80 percent. If the acid concentration is less more chemical will need to be added.

If the solution contains other acids such as acetic or citric acid, it will be less effective than a solution containing only propionic acid. Acetic acid is considered to be about one third as effective as propionic acid. Therefore, you would need three times more acetic acid to have the same effect as the recommended rate of propionic acid. For bacterial inoculants, the manufacturer’s recommendations should be followed.

The estimated cost for the acid solution is about $1.20 per pound. The cost of the spraying system including a pump, tank, valve, nozzle and other miscellaneous parts should added to the values in Table 1 but should be less than $1.00 per ton. Costs will be less when the acid is purchased in the off season in large quantities.

The key to selecting the correct application rate will be determining the forage moisture content. An accurate method must be used and good representative samples must be obtained. There can be a large variation in forage moisture in the windrow so sampling will be very important.