Microbial Inoculants for Silage

by Francisco Contreras-Govea and Richard Muck

Introduction

Ensiling is an important means to preserve forage quality. Although silage fermentation occurs naturally under anaerobic conditions due to the native bacteria on plants, the speed and efficiency of the fermentation (pH drop) is variable, depending on the numbers and types of lactic acid bacteria on the crop. The speed of pH drop affects the amount of sugar used by bacteria; the preservation of true protein; the quantities of lactic acid, acetic acid, and ethanol; and finally the quality of the silage. Recently, there have been some significant changes in the types of microbial inoculants available. This fact sheet discusses the different types of microbial inoculants and provides information about their use on silage crops.

What are silage microbial inoculants?

Silage microbial inoculants contain bacteria selected to dominate the fermentation of crops in the silo. Silage inoculants are divided in two categories depending on how they ferment a common plant sugar, glucose. Homofermenters produce just lactic acid and include some species of Lactobacillus like Lactobacillus plantarum, Pediococcus species, and Enterococcus species. The other category, heterofermenters, produce lactic acid, acetic acid or ethanol, and carbon dioxide. Lactobacillus buchneri is the best example of a heterofermenter.

What is the difference in fermentation between homofermentative and heterofermentative microorganisms?

Homofermenters are more energy efficient than heterofermenters. During homofermentation, each molecule of glucose produces two molecules of lactic acid, yielding high dry matter recovery and little energy loss from the silage. Lactic acid is also a strong acid, reducing silage pH more than other acids.

Final silage pH is higher when fermentation is dominated by heterofermenters when compared to homofermenters. For each molecule of glucose used in heterofermentation, one molecule of lactic acid, one of acetic acid or ethanol, and one molecule of carbon dioxide are produced. Carbon dioxide leaves the silage as a gas, resulting in dry matter loss. Acetic acid is not a strong acid like lactic, and ethanol has no effect on pH.

How does a homofermentative inoculant affect silage quality?

Native bacterial populations are highly variable across plants and fields, depending on plant and environmental conditions. Adding homofermentative microbial inoculants helps to drop pH quickly, inhibiting other bacteria and preserving plant proteins. Rapid pH drop and low final pH can inhibit the clostridial bacteria that produce butyric acid. Usually less acetic acid, butyric acid, and ethanol are produced during homofermentation, which improves dry matter recovery by 2-3% compared to heterofermentative fermentation. Moreover, homofermentative inoculants can improve animal performance by 3 to 5%, doing so in about half of the reported research trials (Kung and Muck, 1997). The one down side to homofermentative inoculants is the shift to lactic acid can make corn silage, small grain silages and other normally low-pH silages somewhat more susceptible to heating during feed out (reduced aerobic stability).

How does Lactobacillus buchneri affect silage quality?

Lactobacillus buchneri is the main heterofermentative lactic bacteria used in silage inoculants. These bacteria can convert lactic acid to acetic acid and other products. Acetic acid is a good inhibitor of the yeasts and molds that cause heating and spoilage of silages. So acetic acid can improve bunk life or aerobic stability. Compared to homofermentative inoculants, dry matter losses are similar to or 1 to 2% higher, digestibility is not significantly affected by L. buchneri, but aerobic stability is consistently improved in silages and high moisture corn. However, L. buchneri inoculants do not appear to improve animal performance beyond that expected from keeping silage cool in the feed bunk (long bunk life).

Is there any advantage in combining both types of inoculants?

Possibly. The combination provides a good fermentation and good dry matter recovery while it provides a higher acetic acid concentration and better aerobic stability than a homofermentative inoculant. Moreover, pH decreases faster with a combination inoculant than with an inoculant containing only L. buchneri. There is no published research at this time to know if these products improve animal performance as much as traditional homofermentative inoculants.

When does it make sense to use a homofermentative inoculant?

A homofermentative inoculant is a good choice for legume silage. Legumes, like alfalfa, have lower water- soluble carbohydrates and a greater resistance to pH decline than grasses or corn. Consequently, legume silages tend to have higher pH’s than corn and grass silages, making them more susceptible to clostridial fermentation when ensiled on the wet side (> 65% moisture). A homofermentative inoculant makes the most efficient use of plant sugars for lowering pH, especially when moisture content is marginally high.

Homofermentative inoculants are the best choice when you want to improve the feeding quality of any kind of silage. Homofermentative inoculants maximize dry matter recovery from a well-managed silo because of their efficient fermentation. Although not completely understood, homofermentative inoculants, when effective, improve animal performance by 3-5% (Kung and Muck, 1997).

When does it make sense to use Lactobacillus buchneri?

An inoculant containing L. buchneri may be a good choice when poor aerobic stability has been experienced in the past. The greater acetic acid concentrations produced by these inoculants slow the growth of the yeasts and molds that cause silages to heat and spoil. However, it is important to recognize many heating problems are caused by other silage management issues such as ensiling overly dry crops, low density in storage, poor sealing, low feed out rate and removing more feed from storage than will be fed immediately. These issues should be addressed before looking to a silage additive to help you.

Even if silage management is good, you can still have heating problems during feed out in corn silage, small grain silages and high moisture corn, especially during summer. Because we do not know how warm next summer will be, an L. buchneri or combination inoculant applied to silage prone to spoilage (e.g., corn) may be useful to avoid heating in silages slated for warm weather feeding.

Under what conditions will a corn silage inoculant be most successful?

Times when a homofermentative inoculant is more likely to be successful are in immature corn, overly dry corn, and the day after a killing frost. The limited research data available suggest these may be conditions where natural lactic acid bacterial populations may be lower and/or less competitive than the inoculant bacteria. The L. buchneri inoculants, when applied at or above label rates, appear to be effective over a broader range of conditions than those where homofermenters will succeed.

Do inoculants work equally well on all legume cuttings during the season?

Do inoculants work equally well on all legume cuttings during the season?

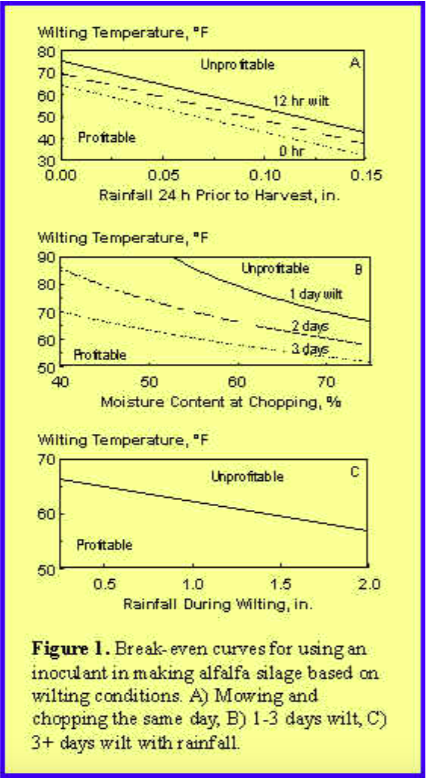

Figure 1 shows the likelihood of a homofermentative inoculant being profitable on alfalfa as affected by harvest conditions (wilting time, average air temperature, rainfall) and assuming a cost of $1/treated ton as fed and return of $3/ton when the inoculant succeeds. Overall, the profitability of an inoculant is more variable in first cutting than in subsequent cuttings. This is because we typically have longer wilting times and a greater likelihood of rainfall during wilting in first cutting, both of which increase the natural lactic acid bacterial population and reduce the chance for an inoculant to succeed. However, it is wrong to assume it is unprofitable to use an inoculant in first cutting. An inoculant is more likely to be successful under good forage harvesting conditions than when a crop lies in the swath for long periods before chopping.

At what silage moisture content do inoculants work best?

An inoculant should work well at any of the recommended moisture contents for the various silo types (i.e., between 45 and 70% moisture). However, fewer types of naturally occurring lactic acid bacteria grow well under drier conditions. This suggests inoculants should be successful more frequently in drier crops.

What is the correct application rate?

Inoculant labeling is highly variable and makes comparing products difficult. The important number is the live lactic acid bacteria applied per unit of crop (inoculation rate). One should buy a product that applies at least 90 billion (or 9 x 1010) live lactic acid bacteria per ton of crop as fed or 100,000 per gram of crop. Some products tell you how many bacteria are in the bag or bottle or how many bacteria are in a gram of inoculant. In those cases, you must calculate the application rate by dividing the number of bacteria in the package by the number of tons the package will treat. Inoculation rates higher than the minimum should be better but are not always so because of differences in the activities of bacteria or the stabilities of the bacterial populations between particular products. Companies should have research data to back up the efficacy of their inoculants and should take measures to ensure the product you buy contains the number and species of bacteria on the label.

What organisms should be present in a silage inoculant?

An inoculant may contain one or more strains of lactic acid bacteria. The most common homofermentative species is Lactobacillus plantarum. Other common homofermentative species include various Lactobacillus or Pediococcus species and Enterococcus faecium. Lactobacillus buchneri is the heterofermentative species used to improve aerobic stability. Be skeptical of products containing other species.

Are there performance difference between specific strains of an organism?

Yes. For example, not all Lactobacillus plantarum strains grow at the same speed. Some L. plantarum strains may grow better on alfalfa, others better on corn. Some strains may grow better under drier conditions or higher temperatures than others, etc. Because of these differences, it is important to use a product labeled for the crop you are ensiling. If a product is labeled only for corn silage, don’t use it on alfalfa and vice versa.

Is there a performance difference between dry and liquid products?

Some inoculants are applied as a dry powder while others are diluted with water and sprayed on the crop. Both dry and liquid products can be effective. However, because these bacteria cannot move around, a liquid sprayed on the crop at the chopper provides the best distribution of an inoculant on a crop. Also, the bacteria in a liquid product should begin working faster than a dry product, where the bacteria need to be moistened by plant juices before they can begin to grow. Finally, most inoculants need to be kept cool and dry prior to use to maintain the activity of the bacteria. This is easiest with the liquid applied products that usually come as dry powders in small packages, which can be placed in a refrigerator.

There are two issues of concern in using liquid products. First, do not use chlorinated water to dilute the product as chlorine can kill the lactic acid bacteria if the chlorine level is too high (above 1 ppm). If chlorinated water must be used, a pool tester will determine if chlorine concentration in the water is less than 1 ppm. If it is above 1 ppm, either allow the dilution water to sit open to the air overnight (so the chlorine level is reduced), or look for a product with compounds to neutralize the chlorine.

Second, once an inoculant has been diluted and is ready for use, it generally needs to be used within a 24-hour period. Consequently, some product is wasted if the forage harvested is less than expected due to weather, breakdowns, etc.

How can I tell if I am purchasing a good product?

It is difficult to compare one inoculant with another, but there are some things to look for in purchasing a product. First, look for a product that guarantees to supply at least 90 billion live lactic acid bacteria per ton of crop. Second, be sure to buy a product labeled for the crop you are going to ensile or a similar crop. Third, don’t be shy about asking for research data (preferably independent research) to support claims for the product and for information about measures the company takes to ensure that you receive a product containing the number and species of bacteria stated on the label.

Can I use leftover produce from this year for the next harvest season?

No, if a package is opened. Open packages should be used soon because the inoculant will absorb moisture from the air, which will potentially cause the bacteria to die.

Yes, if you have unopened packages at the end of ensiling.

Inoculants may not look like living products, but they are. So it is crucial to treat them like living organisms, especially if you want to use a product purchased this year for next year’s crop. Most products state they should be kept cool and dry. This is critical for keeping the bacteria alive. So do not store these products inside a shed or garage that gets over 100°F or in humid environments like a milkhouse. When keeping inoculants between harvests, they should be stored in a refrigerator or a freezer until you want to use them. Products applied as liquids generally come in small containers that are more convenient for keeping until the following year. We suspect, but are unaware of any research, that these products will fare better over winter than the bigger bags of products applied as dry powders.

References

Kung, L., Jr., and R.E. Muck. 1997. Animal response to silage additives, p. 200-210 Silage: Field to Feedbunk, Vol. NRAES-99. Northeast Regional Agric. Engng. Service, Hershey, PA.

Muck, R.E., and L. Kung, Jr. 1997. Effects of silage additives on ensiling, p. 187-199 Silage: Field to Feedbunk, Vol. NRAES-99. Northeast Regional Agric. Engng. Service, Hershey, PA.

Focus on Forage – Vol 8: No. 4

© University of Wisconsin Board of Regents, 2006

Francisco Contreras-Govea, Agronomy Research Associate

University of Wisconsin-Madison

Richard Muck, Ag Engineer

US Dairy Forage Research Center

richard.muck@wisc.edu