Prevent Hay Mow and Silo Fires

by R.L. Tormoehlem, R.G. Koegel, H.D. Bruhn and D.V. Jensen

Numerous barn and silo fires occur annually in Wisconsin. Barn fires, usually caused by spontaneous ignition of hay, occur during and after the haying season.

Numerous barn and silo fires occur annually in Wisconsin. Barn fires, usually caused by spontaneous ignition of hay, occur during and after the haying season.

Silage may spontaneously ignite when it is ensiled at less than 40 percent moisture. Barn and silo fires destroy human lives as well as buildings, equipment, feed and livestock.

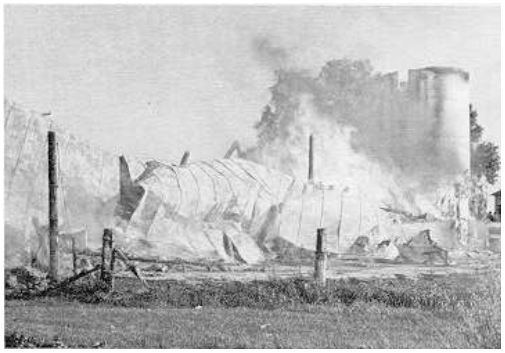

After this barn fire, only the useless sheet metal roof and the remains of the water pipes and stanchions were left to haul away. The silo was badly damaged. Luckily the wind was favorable and, with the shielding provided by the silo, the house was saved.

Hay Mow Fires

Causes

A pile of hay or straw that contains more than 30 percent moisture is a fire hazard. Whether it actually burns depends mainly on the size of the pile and the materials surrounding it. If the heat developed in the pile can readily escape, the hay or straw only turns brown or gets moldy. If there is enough hay or straw around a hot spot to prevent the escape of heat, and a slow infiltration of damp air, the hot spot will burn.

NOTE: Chopped materials (hay, straw, corn stalks) stored in a pile are more likely to spontaneously ignite than the same materials in bale form.

Measuring Temperatures

Drive a pointed tube into the stored hay and lower a thermometer into the tube. If you don’t have a thermometer, drive an iron rod into the material and leave it for fifteen to twenty minutes. If the rod is too hot to hold in your hand when you take it out, the situation is critical.

FIRST STAGE HEATING

- Carbohydrates combine with oxygen to yield carbon dioxide, water, and heat.

- Temperatures may reach 100 degrees F.

SECOND STAGE HEATING

- Heat is produced by bacterial and fungal activity.

- Temperatures may reach 160 to 170 degrees F.

THIRD STAGE HEATING

- Oxygen combines with highly oxidizable material produced during second stage heating.

- This process starts at about 130 degrees F and may reach 190 degrees F, when the situation becomes critical.

- The temperature will rise to the kindling point if enough oxygen and crop moisture are present to generate heat faster than it can escape.

Action

- Check temperature daily when it reached 130 degrees F or higher.

- Above 160 degrees F, check temperatures at least every two or three hours.

- If the temperature reaches 190 degrees F, notify your fire department and insurance company. Remove the hay, and have fire-control equipment ready. Be alert for burned-out cavities. Hay or straw under spontaneous-combustion conditions will smolder in a pile, and may flame up as air strikes it. Remove material from vicinity of buildings.

Precautions

- Don’t store hay at more than 30 percent moisture unless treated with a proven preservative.

- Don’t store chopped hay on top of baled hay if either is damp.

Silo Fires

Causes

Silage stored at less than 40 percent moisture can ignite. This large mass of stored material generates heat that cannot dissipate quickly enough, and a slow movement of air into the silage provides oxygen necessary for combustion.

Measuring Temperature

- TOP-DOWN METHOD

Drive a pointed tube into the silage and lower a thermometer on a lightweight wire. Take several temperature readings, starting near obvious hot spots and moving outward. Because the fire will seek out air pockets in the silage, you may find several hot spots.

NOTE: Since a burned-out cavity may exist, a long ladder or board should be laid across the silage’s surface and the person inside the silo should wear a safety harness. - THROUGH-THE-DOOR METHOD

If the fire is well below the silage’s surface, you may have to take temperature readings through the chute doors. Drill a hole in the door just large enough to insert the probe. Use a probe with 18-inch sections that can be screwed together as it is driven into the silage. Insert a chemical thermometer, using wire stiff enough to push the thermometer into the probe.

NOTE: Electronic thermometers, which are more convenient to use, are also available.

Heating Stages

The heating stages in a silo fire are the same as those in a hay mow fire.

NOTE: The first and second heating stages occur normally during silage fermentation.

Action

- Above 160 degrees F, check temperatures at least every two or three hours.

- If the temperature reaches 190 degrees F, notify your insurance company and fire department. Be sure to notify your insurance company – they may agree to pay for feed loss if you have to unload the silage to avoid heat damage and loss of the silo

Extinguishing Silo Fires

- KNOCKDOWN

If a door has burned through or the fire has progressed to the upper surface of the silage, some flame is likely. In this case, open doors and other coverings to let smoke, gases and steam escape, then have the fire department knock down the flame with water. - WATER INJECTION

If you don’t see open flame, the fire may be several feet under the silage’s surface. First locate the hot spots using the methods described under “measuring temperatures.” Once located, the hot spots can be injected with water using a probe with small holes drilled near the point. Be sure to leave the probe in each hot spot for several minutes before moving to the next. Reasonable amounts of pure water won’t damage unburned silage. However, the wetting agent used in fire fighting, because of its laxative action on cows, makes silage useless. - UNLOADING

Once the open flame or hot spots have cooled, remove burned and damaged silage using the silo’s unloader.

NOTE: If the unloader hits a hot spot, an open-flame fire may flare up. You can prevent or reduce the likelihood of this by thoroughly soaking the silage’s surface prior to unloading.

Precautions

- Be sure the material you ensile has at least 40 percent moisture. For the exact procedure, see publication AI 628, Determining Crop Moisture Content, available at your county UW Extension office.

- Alfalfa that is too dry to leave gum deposits in the blower is likely to spontaneously ignite in the silo.

- Keep air out of the silo. This will reduce the rate of oxidation. Seal leaks and cracks at base and doors before filling.

- Silo fires often start just inside the doors and burn gradually upward. Anyone entering a hot silo should be very cautious – there is always a danger of dropping into a burning pocket that can’t be seen at the surface.

- NOTE: Toxic or combustible gases may by present. Completely ventilate any suspicious silo with the blower before entering, and take care that no sparks are generated. Consult your fire department.

University of Wisconsin-Extension, Cooperative Extension, in cooperation with the U.S. Department of Agriculture and Wisconsin counties, published this information to further the purpose of the May 8 and June 30, 1914 Acts of Congress; and provides equal opportunities in employment and programming including Title IX requirements.

R.L. Tormoehlen was Assistant Professor of Agricultural Engineering, University of Wisconsin-Madison; and Cooperative Extension Service, University of Wisconsin-Extension. R.G. Keogh is Professor of Agricultural Engineering, University of Wisconsin-Madison; and Research Agricultural Engineer, U.S. Dairy Forage Research Center. H.D. Bruhn is Emeritus Professor of Agricultural Engineering, University of Wisconsin-Madison. D.V. Jensen is Emeritus Professor of Agricultural Engineering, University of Wisconsin-Madison, and University of Wisconsin-Extension, Cooperative Extension.

Produced by the Department of Agricultural Journalism, University of Wisconsin-Madison.

This publication is available from your Wisconsin Extension office or from:

Agricultural Bulletin, Rm. 245

30 N. Murray St.

Madison, Wisconsin 53715

Phone 608-262-3346

Editors, before publicizing, contact Agricultural Bulletin to determine availability

![]() A2805 Prevent Hay Mow and Silo Fires (1989)

A2805 Prevent Hay Mow and Silo Fires (1989)