Machinery Designs and Adjustment for Minimized Field Losses

by Ronald T. Schuler, Extension Agricultural Engineer

Biological Systems Engineering Department

University of Wisconsin-Madison

Producing quality forages with a minimum field loss requires the proper selection, adjustment, and operation of the forage harvesting equipment. Farm machinery manufacturers continue to make improvements to increase productivity and minimize losses. Frequently when selecting machinery, a new design may improve productivity but in some cases the producer may have to sacrifice some added forage losses.

The key machine in the forage harvesting system with respect to field losses is the mower-conditioner. Its performance influences losses directly through shatter losses during operation and indirectly through its impact on the drying rate after mowing and conditioning. The longer the crop lays in the field until harvesting, the greater the risk of precipitation on the windrow which reduces forage quality.

Lack of proper machine maintenance and adjustment causes the biggest difference in forage harvest losses from farm to farm. A good operator who maintains losses at a minimum must be familiar with proper maintenance and adjustments to match crop conditions. Some of these harvesting machines have many adjustments that influence the magnitude of the field losses.

MACHINE DESIGNS

One of the biggest changes in forage harvest machine design has occurred in the mower-conditioner where there has been an increase in rotary, also called disk mowers and, to a lesser degree, impeller conditioners. With respect to balers, the increase in mid-size and large square balers requires drier forage at harvest which can lead to higher losses because of the greater risk to weather related damage and larger leaf loss.

Mower-Conditions

The sickle cutterbar mower has been utilized for over a century but is limited to a forward speed of 7 to 8 miles per hours when well maintained. In the mid-1970’s the rotary mower became more available to U. S. producers. The European design was used primarily on grasses but has advantages such as greater forward speeds and better performance in lodged crops.

One concern as the rotary mower was introduced was the persistence of the alfalfa stands after using this mower. Mueller et al. (1996) at the University of Wisconsin reported no differences in yield and plant stand between mower-conditioners with sickle and rotary cutterbars for the alfalfa cuttings following these machines. Therefore, they concluded the rotary mower did not reduce alfalfa stand when compared to the sickle cutterbar.

Since the mid-1950’s, the standard conditioning system was rolls to bend and crimp the alfalfa stems to increase the drying rate. More recently, the impeller, also referred to as finger or tine, conditioning system has created interest. Like the rotary cutterbar, this European design was used primarily on grasses. Instead of crimping the crop, the impeller blades rub or abrade the waxy surface on the stems. The impeller system provides a greater throughput capacity while maintaining effective conditioning. Another advantage was that it allows the large airflow created by the rotary cutterbar to pass through the rear of the machine. This is important in light crops because much of the air discharging from the front of the machine with conditioning rolls creates strips of uncut crop.

Several studies evaluating the losses associated with these cutterbars and conditioning systems have been conducted. In Michigan, Rotz and Sprott (1984) reported the sickle cutterbar had significantly less respiration loss than the rotary cutterbar, Table 1. There was no difference in shatter loss between the two cutterbar designs and two conditioning systems. The conditioning systems, roll and impeller, were very similar with respect to respiration and shatter losses, Table 1.

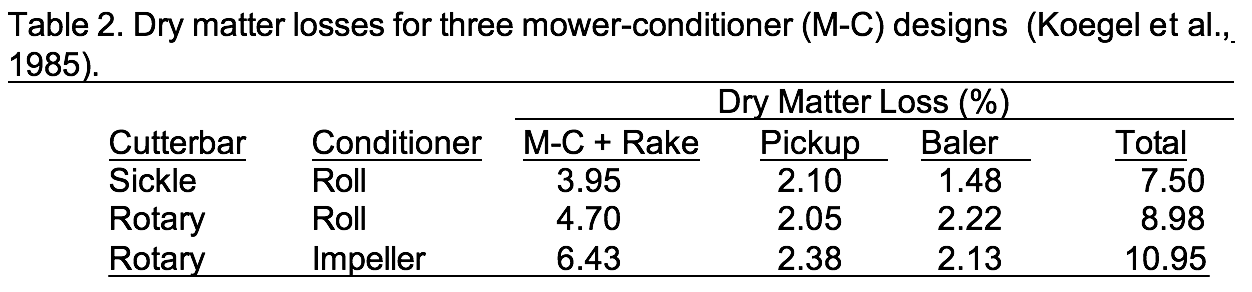

In Wisconsin, Koegel et al. (1985) and others compared three machines from mower-conditioning to baling the crop, Table 2. The losses were one percent higher for the rotary mower-conditioner with rolls compared to the sickle mower-conditioner with rolls after raking, but the differences were not considered significant. The impeller conditioner had significantly higher losses after raking when compared to the roll conditioner. At the baler pickup for the small square baler, there were no significant differences between the windrows produced by the three machines. No significant differences were present at the bale chamber of the small rectangular baler, although the rotary machines had more than one-half percent greater loss. For the total harvesting losses, the rotary machine with the impeller conditioner had losses nearly 3.5 percent higher than the sickle machine with roll conditioner. The rotary machine with roll conditioner was in the middle and considered not significantly different from the other two machines.

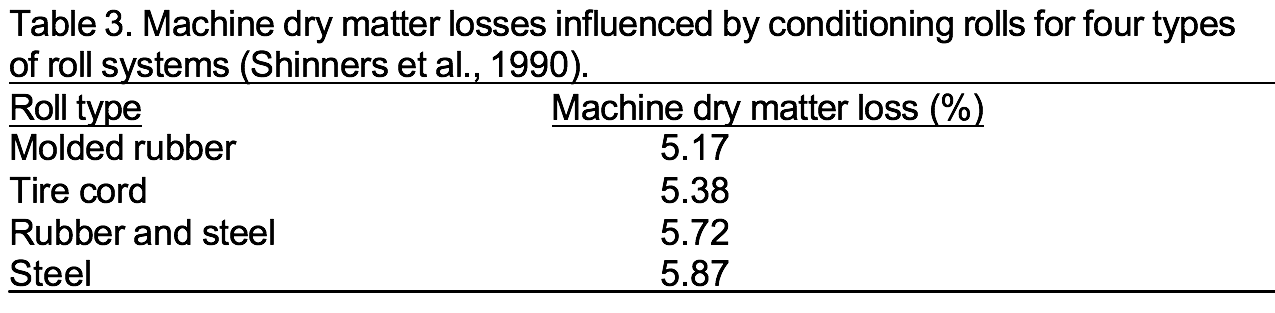

Several types of conditioning rolls are available from the manufacturers and have some influence on losses. Differences are based on the roll material. At Wisconsin, Shinners et al. (1990) compared four roll systems: 1.) intermeshing molded rubber, 2.) intermeshing tire cord, 3.) one rubber and one steel roll and 4.) two intermeshing steel rolls. The respective machinery manufacturer representatives completed the adjustments of the rolls with respect to roll spacing and pressure. The system with the intermeshing steel rolls tended to have the highest losses and was significantly greater than the intermeshing molded rubber rolls, Table 3. There was no difference in the dying rates.

Rakes, Mergers and Tedders

Side delivery rakes have been available for nearly a century, but wheel rakes and rotary rakes have joined the marketplace. The wheel rake’s primary advantage over the side delivery rake is the gentle manner with which it moves the crop, resulting in low losses. But because it requires contact with the soil, it tends to mix rocks and previous crop residue into the windrow.

The rotary rake is another design brought to the U. S. from Europe where it was very successful on grasses. In Michigan, Rotz and Sprott (1984) evaluated rotary rakes and found their losses nearly twice that of a side delivery rake. Some of these higher losses can be attributed to the acceleration of the forage when the tines of the rake contact the crop.

As for mergers and inverters, very little information is available about losses. The best method to evaluate these machines for potential losses is to consider the degree of crop acceleration during machine operation. If the machine gently handles the crop, low acceleration, the shatter loss will be low. This was true of the rakes where wheel rakes have the lowest losses.

Harvesting Equipment

Balers and forage harvesters are both included in this discussion of harvesting equipment. All these machines have a pickup at which much of the field loss occurs. The two major design factors that influence the loss at the pickup are the pickup speed relative to the forward speed and the speed at which the crop is elevated by the pickup into the machine. The forward speed must be reasonably matched to the pickup speed. This is especially true when harvesting alfalfa as dry bales. If the forward speed is slow relative to the pickup speed, the pickup fingers will comb the windrow stripping leaves, allowing them to fall to the ground. If the forward speed is too fast for the pickup, a portion of the windrow may remain on the ground.

The apron pickup was designed for windrowed grain. With the apron design, also referred to as the Melroe pickup, the windrow is elevated more slowly than the conventional pickup. Some mergers utilize this design.

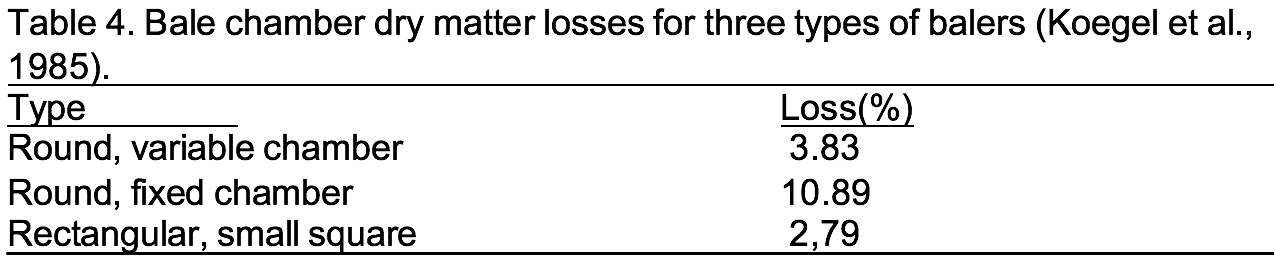

On balers, field losses occur in the chamber area and varies with design. For balers, chamber losses can be significant. In a Wisconsin study, Koegel et al.(1985) compared a small rectangular baler with two round baler designs. One round baler was a variable chamber design where radial pressure is maintained throughout bale formation. The second round baler had a fixed chamber where pressure is applied only after the bales fills the chamber. The small square baler had the lowest losses, Table 4. The variable chamber losses were about one percent higher than the rectangular baler but were not significantly different. The fixed chamber round baler had nearly eleven percent chamber loss that was much larger than the other balers.

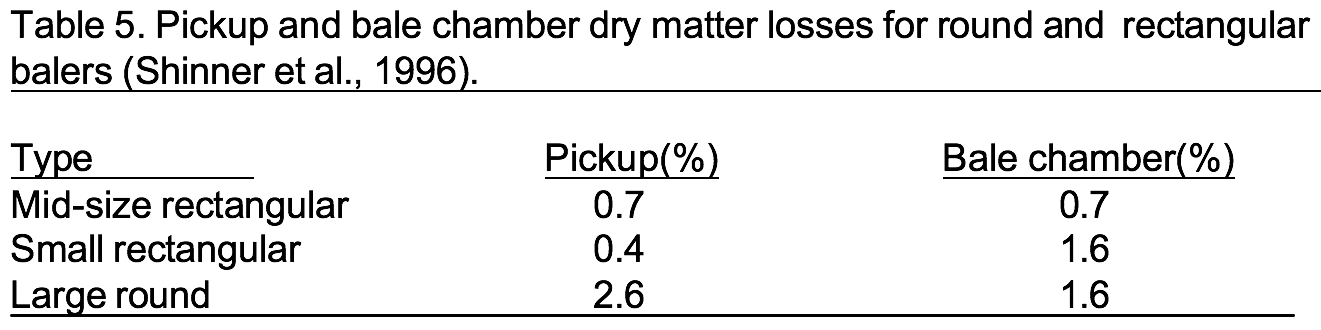

Shinners et al, (1996) found the pickup losses were much higher for the round baler than the small and mid-size rectangular balers, Table 5. Also, they found the mid-size balers had a lower chamber loss than the small rectangular and large round balers, Table 5. Evaluating the forage from 14 to 32 percent moisture, they also found that the baler chamber losses of the mid-size baler was less affected by moisture than the other two baler designs. The closed chamber design on the mid-size baler contributed to the lower losses.

In another Wisconsin study, Shinners et al. (1991) compared two small rectangular balers with bottom and side feed chambers. They studied pickup and bale chamber losses. The bottom feed chamber baler had lower losses in both cases. For the pickup losses, the bottom feed had 1.09 percent versus 1.31 percent for the side feed baler. The bale chamber loss was 2.28 percent and 2.66 percent respectively.

MAINTENANCE AND OPERATION

Proper operation and maintenance of the mower-conditioner is the key to keeping losses at a minimum during the remainder of the harvesting operations. The mower-conditioner has many adjustments that influence the losses directly as shatter losses and indirectly due to its impact on the drying rate in the windrow.

Mower-Conditioners

Some of the mower-conditioner adjustments depend on the cutterbar and conditioner designs. The two primary cutterbar adjustments are height and angle. The cutterbar needs to be adjusted to leave the desired stubble height that will influence yield. The cutterbar angle adjustment is important in lodged crops and depends on the direction of travel relative to the direction of lodging. If operating in the direction of lodging, the cutterbar must be tilted forward or downward. When operating opposite to the direction of lodging the cutterbar angle can be closer to horizontal.

Another adjustment, which can cause losses if not made correctly, is the support spring tension. The cutterbar, in some cases the conditioning system also, is supported by a large spring. If the spring tension is too high, the cutterbar will tend to bounce during operation, resulting in uneven or wavy stubble. If the tension is too low, the risk of damage due to striking an obstruction such as a rock is increased.

The sickle mower-conditioner has a reel, which impacts the losses. In most cases, reel adjustments include reel position (vertical and horizontal), speed and timing. These adjustments need to match crop conditions. For example, in a lodged crop, the reel needs to be moved forward and down, reel speed needs to be increased, and the timing should be delayed.

The cutterbars should receive periodic maintenance to ensure minimum losses. The sickle cutterbar will require more frequent maintenance such as sharpening the knives on the sickle and servicing the guards. The knives on the rotary cutterbar require periodic sharpening even if they appear to continue performing very well.

When adjusting the conditioning system, the operator must balance good conditioning against excessive shatter losses. The forage crop must be adequately conditioned to ensure rapid drying but not over-conditioned, causing high losses. The roll and impeller conditioning systems have different adjustments for obtaining good crop conditioning.

The adjustments on the roll conditioner include clearance, pressure, and timing for the intermeshing rolls. For light crops or low yields, the roll clearance and pressure should be reduced. For large yields, the clearance and pressure should be increased. The roll timing needs to be adjusted if the intermeshing rolls are interfering, causing over-conditioning and excessive support bearing loads. The operator should check the conditioned crop to ensure the adjustments are correct. The stems should be cracked but no discoloration should be present due to over-conditioning. A dark green color indicates cell walls are ruptured and over-conditioning has occurred.

For the impeller conditioner, there are usually two adjustments that influence crop drying rate and losses. They are impeller speed and clearance between the impeller and conditioning hood. A slower speed is used for alfalfa while a higher speed is used for grasses. For more aggressive conditioning the hood above the impeller can be lowered. On some older impeller conditioners, a set of adjustable, stationary tines intermesh with the tines on the impeller. The degree of intermeshing determines the intensity of the crop conditioning.

Rakes, Mergers, and Inverters

The primary adjustment affecting losses of rakes will be the operating height, except for the wheel rake that needs to be in contact with the ground. This height needs to be adjusted to ensure the crop is completely picked up without picking up rocks and old crop residue. For the mergers and inverters, the height of their pickup needs to be adjusted to ensure the windrow is also completely picked up.

Most of these machines’ performance is affected by the forward speed. Usually an excessive forward speed leads to excessive field losses.

Crop moisture content is a major factor in the losses created by this equipment. Raking and inverting should be done with crop moistures over forty percent and tedding should be done at moistures at sixty percent or more. Although research is very limited on mergers, moisture contents over forty percent should only be considered.

Forage Harvester and Balers

The primary adjustment on these machines is the pickup height to ensure the entire crop is harvested. Also the harvesting should be completed in a timely manner before it over dries when losses can potentially become much larger.

Consider adding an acid preservative to allow baling dry hay at higher than recommended moisture contents when losses will be less. This reduces the risk of precipitation causing losses in crop quality as well.

In conclusion, the biggest difference in forage harvesting losses from farm to farm is not the brand or design but how well the equipment is maintained, adjusted and operated. Time used by the operator is well spent checking to ensure the crop is being properly mowed and conditioned by the mower- conditioner and adjusting the balers and forage harvesters to ensure total windrow is harvested. Also these operations should be completed in a timely manner to ensure minimal field losses and a high quality forage crop.

Equipment design has a very key role in shatter losses and productivity.

Some of the equipment designed for grasses in Europe increase productivity but have increased losses when used to harvest alfalfa. When purchasing this equipment, the producer must decide whether they want to sacrifice some added losses for improved mower-conditioner productivity.

For more details on the research see the following:

Mueller, D. H., D. J. Undersander, and D. L. Frye. 1996. Disc and Sickle Mower- Conditioners Affect on Stand Persistence and Yield. UW-Madison Arlington Research Station, Arlington, WI.

Koegel, R. G., R. J. Straub and R. P. Walgenbach. 1985. Quantification of Mechanical Losses. Transactions of the ASAE, 28(4)1047-1051.

Rotz, C. A. and D. J. Sprott. 1984. Drying Rates, Losses and Fuel Requirements for Mowing and Conditioning Alfalfa. Transactions of the ASAE, 27(3)715-720.

Shinners, K. J., R. G. Koegel and R. J. Straub. 1990. Leaf Loss and Drying Rate of Alfalfa as Affected by Conditioning Roll Type. ASAE aper 901048. St. Joseph, MI, 14 pp.

Shinners, K. J. R. J. Straub, R. L. Huhnke and D. J. Undersander. 1996. Harvest and Storage Losses Associated with Mid-Size Rectangular Balers. Applied Engineering in Agriculture, 12(2)167-173.

Shinners, K. J., R. J. Straub and R. G. Koegel. 1991. Performance of Two Small Rectangular Baler Configurations. ASAE Paper 911581, ASAE, St. Joseph, MI. 12pp.