Silage Preservation: First Things First

by Brian J. Holmes

bjholmes@wisc.edu

Harvest at Correct Stage of Maturity

Why? High levels of readily available carbohydrate are needed to ferment into acids.

What Stage? Alfalfa – early to mid bloom, Corn – 1/3 – 1⁄2 half milk line

Harvest at Correct Moisture

Why? Too dry…

- high porosity (oxygen penetration)

- reduced acid production

- reduced thermal mass (rapid heating)

Too wet…

- Clostridial fermentation (Butyric acid)

- Leachate discharge (nutrient losses)

What Moisture? Alfalfa – 60-65%, Corn – 65-70%

Chop to Correct Particle Length

Why? Shorter particles pack better and release more soluble carbohydrates

How? Set knives to obtain 3/8th inch TLC for hay and unprocessed whole plant corn and 1/2 – 3/4 inch TLC for processed whole plant corn.

Size Silo Properly

Why? To remove silage at a high rate (keeps ahead of spoilage). To avoid safety problems (avalanche of overhang).

How? Select face cross section to achieve 12″ per day removal based on volume removed each day. Stack silage so it is no higher than the unloading equipment can reach (no overhangs). Remove no less than 6″ per day.

Seal Silo Cracks and Holes

Why? Limits oxygen penetration

How? JetCrete, Epoxy, Grout, Plastic sheets

Harvest at High Enough Rate to Fill Silo in Three Days

Why? While silos are open, forage is exposed to oxygen thus supporting microbial deterioration. Exposed forage is also susceptible to precipitation which can leach soluble carbohydrates.

How? Size silos small and/or provide enough equipment and labor to harvest and transport forage quickly.

Pack Forage to a High Bulk Density

Why? High bulk density has low porosity (limits rate of oxygen transmission through silage)

How? Proper forage moisture (60-70%), Thin filling layers (<6 inches), Heavy Tractor(s), Pack continuously, Pack whole surface (keep packing slope shallow), Multiple packing tractors

Seal Forage Against Oxygen Penetration

Why? Oxygen supports aerobic microbial decomposition of silage.

How? Slope forage surface to drain runoff water away from silo wall, cover top surface with 6-8 mil plastic within 24 hrs of filling, weight plastic uniformly to prevent plastic billowing in wind, seal edges with soil or gravel filled bags. Manage vermin which can cause holes. Inspect plastic weekly, patching holes as found.

Maintain Tight, Smooth Feed Out Face

Why? Ragged silage has larger surface area exposed to oxygen and fissures and cracks allow oxygen to penetrate deep into silage.

How? Scrape silage at feed out face in a downward motion of the loader bucket or use a facer to remove forage.

Remove Only the Forage that will be Fed in One Feeding

Why? Removed silage is low density which allows oxygen to penetrate deeply. Rapid heating can result.

How? Pay attention to how much material needs to be removed.

Practice Safely

Why? Injury and death are expensive! It can happen to you.

How?

- Four wheel drive packing tractor

- Roll over protection on tractor and use seatbelt

- Experienced pack tractor driver

- Keep pedestrians (especially children) away from filling areas.

- Keep packing surfaces at 3:1 slope or shallower

- Don’t fill higher than unloader can reach (no overhangs)

- Face wall side of silo when covering and weighting (don’t back up to edge), consider guard rails at wall top.

- Use trailer dump while parked only on solid surfaces

- Avoid approaching the feed out face (avalanches are real)

- Avoid standing/walking on top of silo near the feed out face (avalanches are real)

- Don’t place forage on top of plastic cover when adding new feed (pull back the plastic first)

How much value can be saved by implementing good silage management practices?

The answer to this question depends on your current management practices. If you need to improve in some practices and can be viewed as doing a moderate job of management, some improvement in savings can be obtained. If on the other hand, large improvement in practices are needed, much greater savings are possible. To help address this issue, a spreadsheet (Determining Value of Improved Silage Management) is available on the Harvest and Storage page of the UW Extension Team Forage web site located at URL: https://fyi.extension.wisc.edu/forage/files/2014/02/FeedLo-7-8-11.xls

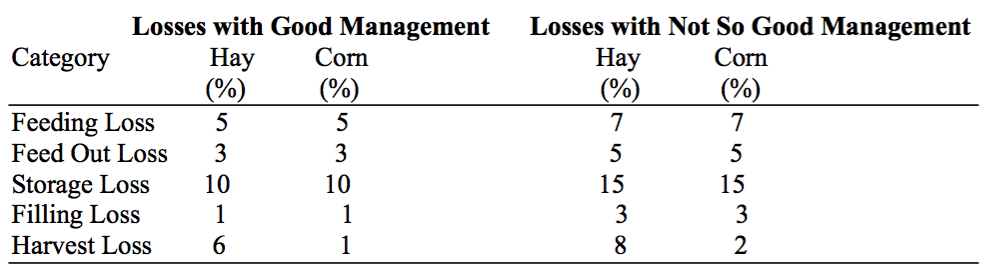

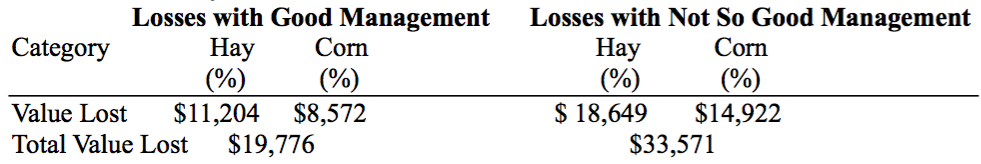

The Determining Value of Improved Silage Management spreadsheet was used with the following assumptions to estimate the benefit of moving from not so good management to good management:

100 cow herd with replacements

Hay Silage Value = $125/TDM

Corn Silage Value = $100/TDM

Results of the analysis are:

With these assumptions and those not presented about the ration formulation, the value of moving from not so good management to good management is $13,795/year ($33,571- $19,766). You can use this spreadsheet to enter your own assumptions about herd size, rations and estimated losses to find a savings for your situation for each management change you attempt and for the total savings.

October 25th, 2008

University of Wisconsin – Madison

Biological Systems Engineering Department

460 Henry Mall

Madison, WI 53706