If drying is unavoidable, consider allowing crops to dry in the field as much as possible to reduce energy costs. Keep in mind, however, that there is a point where field losses will increase. One also has to account for the time needed to harvest grain based on the capacity of your equipment and the risk of weather damage or weather impeding harvest. The University of Kentucky’s Grain Storage System Website provides a calculator to estimate the cost of harvest losses versus drying costs (Link to tool) [1]. Chapter 8 in the Corn Handbook on Corn Harvesting by Huitink discusses how to estimating field losses [2].

The moisture content of the standing grain at harvest initiation will depend on weather conditions, the amount of grain to harvest and harvest and drying capacity. Corn kernel mechanical damage during harvest is usually lowest between 19 percent to 24 percent moisture [3,4].

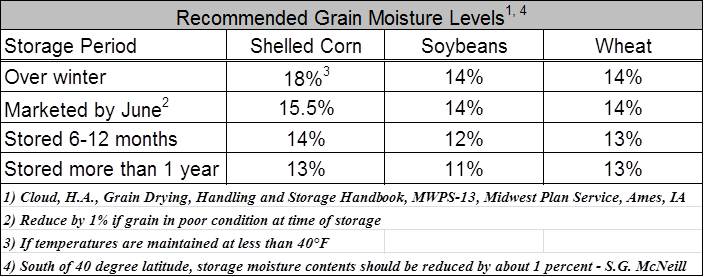

It is important not to dry more than necessary. Drying grain to a moisture content lower than required removes water that would otherwise be sold (0.65 pounds per percentage point of moisture per bushel). When grain is dried more than is necessary, drying costs will rise while income from grain sales will be reduced. If 1000 bushels of corn was dried to 12% instead of 15%, this would result in a 3.4% shrink loss or a reduction of 34 bushels to sell [6]. Table 1 lists the recommended grain moisture levels depending on the expected length of storage.

When using mechanical drying, grain with large amounts of foreign material should be cleaned before drying to reduce the amount of energy used to dry foreign material and to increase airflow during drying and storage. Using heat recovery, using the maximum plenum temperature and dryers with features such as grain turners or staged temperature dryers can also help reduce energy use. Processes such as combination drying, in-bin cooling and dryeration can increase dryer capacity, reduce energy use and improve grain quality.

Drying with warmer outdoor air temperatures reduces the energy required to dry for both natural-air/ambient-air drying and high temperature drying. Higher relative humidity or colder air temperature will increase drying costs.

References:

1. University of Kentucky Grain Storage System website. Available at:

http://www.bae.uky.edu/ext/Grain_Storage/calculators.htm

2. G. Huitink. 2008. Corn Production Handbook – Chapter 8 – Corn Harvesting ,MP437, University of Arkansas

Cooperative Extension. Available at: http://www.uaex.edu/Other_Areas/publications/PDF/MP437/chap8.pdf

3. S.G. McNeill, Halich, G.S. 2012. Cost of Harvest Losses vs. Heated Air Drying, Excel spreadsheet application. Available at: http://www.bae.uky.edu/ext/Grain_Storage/calculators.htm

4. S.G. McNeill. August 22, 2012. Personal communication.

5. H.A. Cloud, et.al. 1988. Grain Drying, Handling and Storage Handbook – MWPS-13, Midwest Plan Service, Ames, IA, pg 3.1, Table 3-1. Available at: http://www-mwps.sws.iastate.edu/

6. W. Wilcke. 2004. Costs for Overdrying Crops, Minnesota/Wisconsin Engineering Notes, P103-2004-09.