What is Wood Energy?

Wood energy is captured through the combustion of solid celluloid material found in trees and woody shrubs, and is one of the most important sources of renewable energy providing over 9% of the global total primary energy supply. These materials are found in many areas of Wisconsin, including in forests, other wooded lands, as co-products of wood manufacturing and processing, and from post-consumer wood recycling. To better understand how these materials are harnessed to produce energy, it helps to know in what type or form wood resources can be converted to fuel wood energy infrastructure.

Biomass (a general WI definition) means a resource that derives energy from wood or plant material or residue, biological waste, crops grown for use as a resource or landfill gases. Biomass does not include garbage, as defined in s. 289.01 (9), or non-vegetation-based industrial, commercial or household waste, except that “biomass” includes refuse-derived fuel used for a renewable facility that was in service before January 1, 1998. Wis. Stat. 196.378(1)(ar).

Woody Biomass is the woody parts of trees and other plants, including limbs, tops, needles, and leaves. Sources of biomass include forests, rangelands, and urban tree waste. Biomass is usually a byproduct of managing or restoring forests, treating hazardous fuels to reduce the threat of wildfires, and caring for urban trees.

Cord Wood is the traditional wood fuel, cut to length, slit and air-dried. The energy content of the wood will vary depending on its moisture content and the tree species. Generally, hardwood trees will have higher energy content per cord than softwood mainly due to the wood’s density.

Wood Chips are for larger scale heating and can be an inexpensive fuel, but they require special handling and combustion equipment. Wood chip burning equipment can handle treetops, limbs, scrap or wood waste. Wood chips can be stored outside, which reduces the cost by not requiring an enclosure. However, chip fuel piles require some type of bulk material handling equipment, typically a front end loader. Wood chip combustion systems can require routine, even daily maintenance.

Wood Pellets are a dried, uniform fuel formed from low-grade wood for use in heating and other applications. Wood pellets, because of their dry and consistent nature, are a biomass fuel that is easy to meter, produce heat very efficiently, and require little management on the part of the customer.

Wood Residues

There are also wood energy resources that are referred to as Wood Residues that are often co-products of wood manufacturing and processing, as well as post-consumer wood products and urban wood waste. These sources include:

Forest Operation Residues (Raw Materials process) or woody debris left behind after trees are harvested for timber.

Wood Products Residues (Industrial process) or wood waste from industries that make products from wood, such as cabinet and furniture companies, can also be used to produce energy.

Urban/yard Waste Wood or woody biomass removed after utility workers clear trees from power lines, homeowners trim their hedges, or from storms and land clearing.

Wood Resource Production

Woody Biomass Production in Wisconsin takes multiple forms to derive a variety of benefits to communities around the state. Each of these wood resource production types serve wide-ranging applications, from energy to biomass feedstocks for industrial applications. Some examples include, but are not limited to:

Energy Plantations that grow woody biomass for the purpose of energy production. Some tree species can be grown as crops that produce a lot of biomass in a short time and can be harvested repeatedly before they have to be replanted.

Forest Restoration and Health improves forest health and restores certain ecosystems to the naturally occurring forest type typically by removing unwanted trees and other vegetation to reduce crowding and promote healthy tree growth. Material that is removed can then be used to produce energy that may, in some locations, pay landowners for the cost of removal.

Fuelwood is wood waste, dedicated energy crops, pulp wood, and commercial grade timber that can be used as an energy or bio-products feedstock. Harvesting fuelwood from industrial facilities may become more feasible in areas where the forest products industry is not buying or paying competitive market prices for pulp and commercial grade wood due to mill closures, market shifts or other reasons.

Wood Energy Appliances

Once woody biomass resources have become available, the next consideration is the ideal appliance for harnessing the energy within the biomass. Below is a short overview of the types of wood burning appliances available in Wisconsin.

Wood Stoves are indoor systems that can be freestanding or may resemble a fireplace with airtight doors. The thermal efficiency of EPA-certified wood stoves averages 72% for catalytic wood stoves and 63% for non-catalytic wood stoves.

Hydronic Pellet Boilers are heating appliances that manufacturers have introduced that burn wood pellets and can be installed either indoors or outdoors, Thermal efficiency of these appliances is typically about 80% with some units having greater than 90% efficiency. Pellets for the boiler are stored in a bin next to the boiler. The ash is augered out of the boiler to a receptacle for disposal.

Outdoor Wood Boilers (OWB), sometimes called hydronic heaters, are outdoor wood boilers that have gained popularity as energy prices have increased. OWBs look like small utility sheds and are basically simple fireboxes typically surrounded by a jacket of water.

Wood Chip Boilers: The use of wood chips as a fuel may be a viable alternative for medium to large greenhouses, schools, homes or businesses. Wood chips can be obtained from multiple sources including sawmills, tree maintenance or harvesting operations and furniture manufacturer. Wood chips can be stored in a pile on the ground or in an above-ground or below-ground bind; the surface must have adequate drainage and the large chip piles should not be allowed to stand for extended periods of time without being turned.

Pellet Stoves, Furnaces, and Boilers are appliances that burn pellets made out of wood or other biomass for fuels. The major advantage of a pellet stove, furnace or boiler is the ability to meter the fuel into the combustion chamber

based on current heating requirements. This helps prevent excess fuel in the combustion chamber, which could produce smoke if that heating demand is reduced. These can run unattended for up to 24 hours or more. A pellet system eliminates the time and equipment required to harvest the wood. The thermal efficiency of these systems is typically 80% but can range from 70-85%, and a few models offer efficiencies greater than 90%. Pellet delivery systems are classified as either top-feed or bottom-feed to the combustion chamber.

Top-feed systems contain an auger that meters pellets into the combustion chamber from the top of the system into a steeply pitched chute. The pellets slide down the chute into the combustion chamber by gravity.

Bottom-feed systems contain an auger that meters pellets into the bottom of the combustion chamber. The pellets burn as they move up through the combustion chamber. The ash overflows the top of the fire bowl and is deposited either in an ash pan or pushed out of the chamber to a container outside.

Also, take a look at October 2015 wood stove ratings from the Alliance for Green Heat.

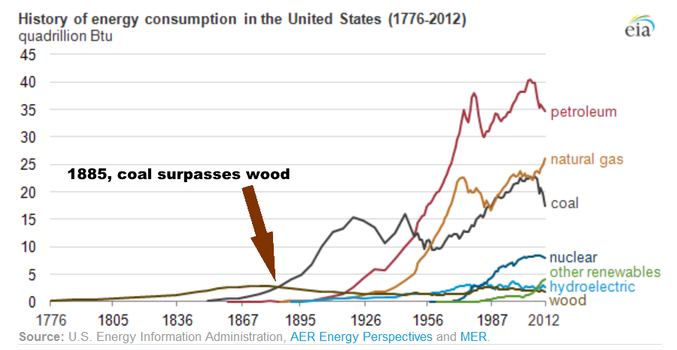

The (short) History of Wood Energy

Wood was the biggest energy provider in the world in the 1800’s, and was the biggest energy provider in the US until 1885 when it was surpassed by coal. Wood was the second largest until passed by petroleum in the early 1920’s

Using wood as a heating fuel is ancient technology that is seeing increased popularity with the advent of modern wood heating appliances. Approximately 200,000 (9%) of Wisconsin homes burn about 1.2 million cords of wood every year as either a primary or secondary fuel source and biomass produces about 1.5% of the energy used in the United States. Today, wood remains one of the largest single sources of renewable energy on earth with uses for electricity production, space and water heating, industrial thermal processing needs, and much more.

For more information about the use of woody biomass in Wisconsin, the US Forest Service has prepared document that outline Wisconsin Woody Biomass Statistics and also a review of the State of Forest-based Industries.

Why Use Wood Energy?

Many people opt for wood, wood pellets, and grains as low-cost alternative energy sources, especially during periods when energy prices rise. Wood fuel contains minimal heavy metals and extremely low levels of sulfur; therefore, the combustion of wood fuel will not create acid rain pollution through sulfur emissions. However, burning wood in the forest does emit significant amounts of nitrous oxide, a GHG, if either by wildfire or broadcast burning for stand improvement. Particulate emissions from wood are controllable through standard emission control devices such as bag houses, cyclone separators, fly-ash injectors and electronic precipitator, and bottom ash is minimal. Usually, wood ash is less than 1% of the weight of the wood and can sometimes be used as fertilizer.

Developing and expanding the use of woody biomass supports forest ecosystem health by improving the economic viability of both forest management and wood products manufacturing. Biomass is a renewable energy source because wood can be continually replenished, which leads to a sustainable and dependable supply. However, proper forest management must be practiced to ensure that growing conditions are not degraded during biomass production. Using woody biomass is also a valuable tool for mitigating climate change by reducing consumption of fossil fuels. Wood combustion produces little net (less than 5%) carbon dioxide, b/c the CO2 generated during the combustion of wood equals the CO2 consumed during the life-cycle of the tree. Transporting wood using petroleum generated some excess CO2.

Woody biomass production and utilization also supports local/rural economies and creates jobs!

Woody Biomass Media

The video below gives an overview of woody biomass opportunities in Wisconsin, including for small-scale residential and large-scale institutional applications. There are also details about the resources available to you from the Wisconsin Statewide Wood Energy Team and its partners.

Biomass 101 by Green Mountain Energy, this video is helpful to gain a better understanding of how biomass energy projects are related.

https://www.youtube.com/watch?time_continue=1&v=HZoPNJGi6ig

What to Think about when Considering a Wood Energy Project

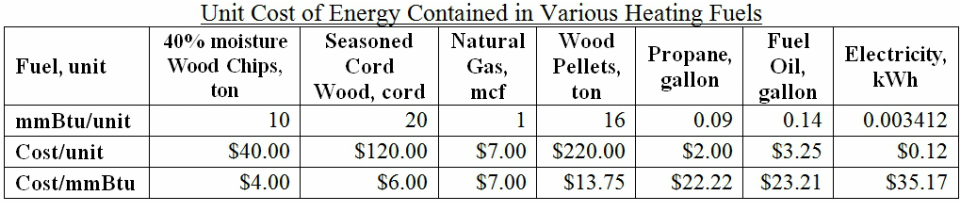

Fuel Types and Costs

Cord Wood: minimal cost (low grade), but labor intensive processing required; drying to 35% (wet basis) or less moisture content desired; bulky fuel requiring manual handling multiple times; due to energy density (and often legal restrictions) the cords cannot be transported long distances cost effectively; cost determined by local availability and market

Wood Chips: typically a byproduct of another economic activity and minimal additional processing required, reasonably consistent particle size allowing for automated handling; due to energy density cannot be transported long distances cost effectively; cost determined locally by market.

Wood Pellets: processed fuel that is a consistent particle size and energy content that allows for easy automated handling, high energy density and is often transported long distances to market; cost tied to that of competing fossil fuels; bulk delivery improves the viability of larger systems.

Consideration of Quality and Quantity of Heat Needed

- Quality of the load: steam, hot water, temperature, pressure, etc.

- The total annual load.

- How might the load fluctuate between seasons and over each day?

- Keep in mind: the higher the thermal load, the more annual savings, and the better economic justification of the project.

Appropriate Wood Fuel and System Size

Selecting the appropriate fuel and system requires detailed analysis, but there are some general rules-of-thumb that can be followed for initial evaluation.

Cord Wood Systems utilize and inexpensice fuel and can provide large cost savings. However, they are typically limited in overall size because of the labor associated with fuel handling.

Wood Chip Systems require substantial handling equipment for automation and large storage volumes. However, as heat loads become larger, the savings from low cost wood chips will provide significant returns on investment.

Wood Pellet Systems use a fuel that is easy to handle with inexpensive automated systems, and their high energy density allows small and inexpensive storage. Wood pellets can easily be used in small and large systems. However, due to the cost of the processed pellet fuel, there is typically an upper size limit where a wood chip system will provide better return on investment.

Heating Distribution System

The ease with which woody biomass systems can tie-in to the existing heating system will have a major impact on project costs. Central systems where one central boiler or furnace is utilized to provide heat to a facility are ideal. A facility with multiply buildings and boiler rooms or multiple rooftop heating units will have a much higher cost for tie-in.

Backup Fossil Fuel Systems

Woody biomass systems typically should have fossil fuel backup systems in place. Often, woody biomass systems are designed to rely on fossil fuel systems to provide some heating in peak demand times. Facilities with aging fossil fuel equipment can retire their worst performers and/or minimize equipment replacement cost through reliance on the woody biomass system for the majority of heating.

Fuel Delivery and Site Access

Cord Wood is often delivered in pickup or dump trucks.

Wood Chips are typically delivered in walking floor tractor trailers, and site access is key design consideration.

Wood Pellets for commercial systems typically require bulk delivery. Pellet bulk delivery is typically from a large grain truck, and site access is a key design consideration.

Storage for all fuels should hold a minimum of 1.5 times the volume of delivery vehicle to allow for deliveries while some fuel remains in storage.

Wood Energy System Design

System Size

Micro Scale: For residential use furnaces use split lengths of firewood to heat which is then circulated through a duct system to various points in the building. Small gasifiers coupled to internal combustion engines and generators can produce up to 100kW of electricity for decentralized use. Micro-scale co-generation is sometimes used for village power applications in developing countries.

Small Scale: Space or process heat for schools (between 1-5 MW), water instead of steam, and low- or high-pressure steam systems.

Medium Scale: Space or process heat for large schools (starting at 5 MW), large commercial buildings, and small industrial facilities.

Large Scale: Forest products manufacturing plants and other industrial facilities like brick and lime kilns.

Cord Wood Systems generally operate effectively between 40 and 100% of their firing rate (25-100% for wood chip systems), which means that one unit may not be able to fully cover both peak and low loads at a facility. One approach to system sizing is to optimize value by minimizing wood system size and capital costs while maximizing fuel savings. This approach utilizes one or more advance combustion units to cover 80-95% of heating demand and relies on fossil fuel systems to cover the last 5-20%. Thermal storage can be used to improve operating ranges and load coverage.

Wood Chip Systems generally operate effectively between 25 and 100% of their firing rate (40-100% for cord wood systems), which means that one unit may not be able to fully cover both peak and low loads at a facility. This presents similar challenges to those described with cord wood systems above. Thermal storage can also be used with wood chip systems to improve operating ranges and load coverage.

Pellet Systems typically have automatic start features and will often be combined with thermal storage to cover 100% of the load at a facility.

Thermal Storage

Hot water thermal storage provides improved performance and efficiency for woody biomass systems.

Thermal storage is required for clean and efficient operation of a cord wood boiler, and allows energy released during an efficient 6-8 hour burn to be utilized for a period of day as demand allows. Rule-of-thumb minimum thermal storage sizing for cord wood systems is 200 gallons per 100,000 Btu/hr of furnace output.

Wood Chip Systems benefit greatly from thermal storage since the thermal mass of the fuel and boiler make system modulation less responsive (i.e. responding to changing heating needs during the day). Thermal storage assists in meeting short term demand until the boiler can ramp up to higher heat demands and storage also provides an energy heat sink to maintain boiler combustion efficiency as system heat demand decreases. Rule-of-thumb for sizing thermal storage for wood chips systems is 100 gallons per 100,000 Btu of furnace output.

Pellet Systems can modulate much more rapidly than chip systems, but can also benefit greatly from thermal storage. In addition to system response benefits, occasional charging of thermal storage can efficiently provide summer domestic hot water (DHW) needs.

Generally, the use of thermal storagealso allows integration of solar thermal heating systems which can improve overall efficiency and assist with shoulder season heating requirements and summer DHW loads.

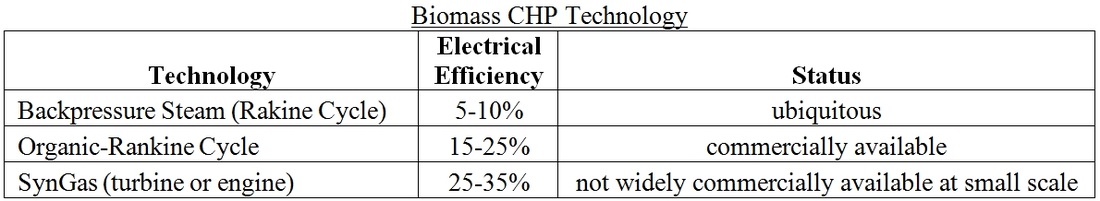

Combined Heat and Power (CHP)

Power generation from woody biomass should be thermally-led to maximize efficiency, with few exceptions. Thermally-led means that power generated is dictated by the facility’s heat demand. This ensures heat is not wasted, and allows for generating electricity at an effective cost of about $0.02/kWh (depends on fuel price/technology). Good candidates for these systems are hospitals and industry that have year round heating or process loads. However, systems can be cost effective for larger seasonal heating loads.

Concerns about Wood Energy

Smoke and Particulate Matter

Wood smoke is responsible for about 13% of all of the fine particle emissions nationally, and wood smoke and fine particles penetrate building envelopes creating odors and raising the level of indoor air pollution EPA standards will impact the wood particulate matter in the air. Particulate matter is produced mostly from outdoor wood stoves that are inefficient. Also, there are over 200 Wisconsin communities that regulate wood smoke.

New boilers burn wood efficiently and effectively and produce very little smoke or ash. Emissions from wood boilers are typically lower in nitrogen oxides and sulfur oxides than fossil fuel boilers, but are usually greater in particulate matter. Wood boilers can be equipped with pollution control devices that reduce particulate matter to bring them as low or lower than fossil fuel boilers, but these devices will increase installation costs.

Visit EPA’s Burn Wise web page for more information about the human health impacts of wood energy. If you have further questions or general inquiries, please feel free to send an email to Scott Sanford at sasanford@wisc.edu or visit our Meet the Team page.