For most greenhouse operators, heating cost is the 2nd or 3rd highest cost in producing plants so it’s an important issue. There are a number of great appliance options, but before switching to wood you need a answer a couple of key questions.

Energy Efficiency First – Can I reduce heating needs more cost effectively than switching to wood energy?

Wood stoves, furnaces or boilers can cost thousands of dollars to purchase and install. If you are concerned about high energy cost, you should have an energy audit done FIRST to help identify potential savings. Things like adding double wall glazing, weather stripping around vents, doors and between the sill board and the ground, replacing an inefficient furnace or converting to bottom heating can reduce energy cost too and often with a faster payback. It also may reduce the size of a future wood burning appliance. Use the USDA Energy Self-Assessment tools (link under Essential Reading) to do your own energy audit to identify and estimate the potential energy savings from energy efficiency measures.

How does heating with wood compare to propane, natural gas or heating oil?

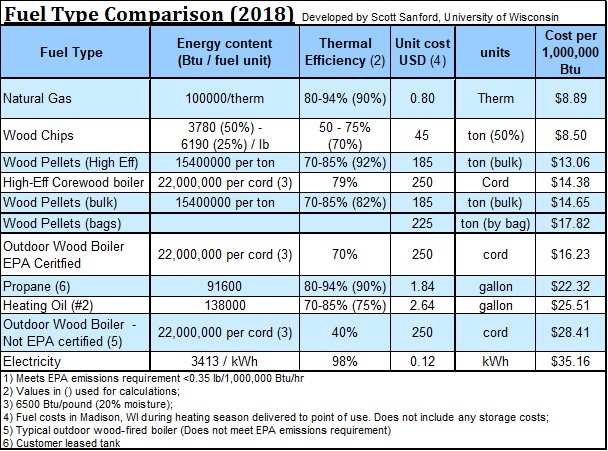

Any comparison between fuels will depend on the local cost and availability of different fuel sources and the efficiency of the appliance the fuel is being combusted in. A long term average cost should be used for comparison rather than short term drops or spikes in prices. Historic energy cost can be found at the Wisconsin State Energy Office website under Statistics/Tables and then Heating Fuels Tables/ Winter Fuel Pricing. These prices are based on weekly surveys of retailers across Wisconsin. For an example, the prices as of Jan 5, 2018 are $1.84 per gallon for Propane, $0.80 per therm for natural gas, $2.64 per gallon for heating oil and $250 per cord for wood, wood pellets at $225 per ton, and wood chips (30% moisture) at $45 per ton. The best comparison is per 100,000 Btu or the requirement to heat a particular structure. For this example we’ll assume a typical propane or natural gas fired heater is about 78% efficiency, Heating oil is 75%, and wood pellets are 80% efficient. A cord wood stove or boiler can range from 20% to 75% depending on the type. For this example we’ll assume 40% for a non-EPA certified outdoor boiler and 70% for a new EPA certified outdoor boiler. The cost per 100,000 Btu of usable heat is as follows:

There are other costs to consider besides the relative cost of the fuel such as labor for stoking and handing fuel, ash disposal and initial capital cost.

What is the best appliance for my greenhouse?

The “Best” heating appliance will depend on fuel availability, labor and area to be heated. A small greenhouse could likely use a cord wood boiler but would likely have to stoke it twice per day with an occasional midnight stoking required during an arctic blast. If nightly trips to the greenhouse are undesirable, than wood pellets would be a better choice. Using cord wood boilers for an acre of greenhouse would require hundreds of cords of wood and space to store it and a person to stoke the boilers all night. This is likely not practical so a fuel that can be handled in bulk by the truckload with automation to feed the boiler (loader, augers and conveyors) is likely a better choice – pellets or wood chips. A large facility may have a dedicated heating plant that can serve multiple greenhouses while a small greenhouse could have a pellet boiler located at one end with a hopper bin adjacent that would hold enough wood pellets for several days.

Essential Reading

| Biomass Energy For Heating Greenhouses |

| Biomass Heating in Greenhouses – Case Studies |

| Greenhouse Unit Heaters – Types, Placement & Efficiency |

| Reducing Greenhouse Energy Consumption – An Overview |

| Using Curtains to Reduce Greenhouse Heating |